NaN / 0

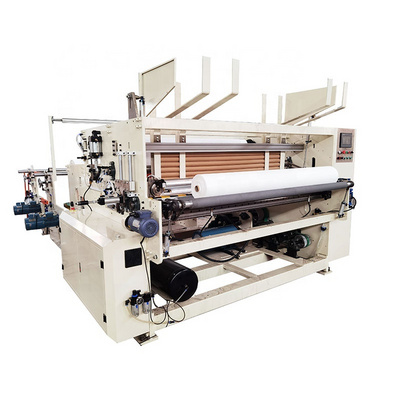

Small Manufacturing Machines Automatic Toilet Tissue Paper Making Machine Price

Get Latest Price

US$ 19000

≥1 Sets

Quick Details

Type:

Slitting Rewinder

Production Capacity:

150-240m/min

Max. workable width:

3000mm

Place of Origin:

Fujian, China

Product Details

Product Description

Small Manufacturing Machines Automatic Toilet Tissue Paper Making Machine Price

Product Application

Small Manufacturing Machines Automatic Toilet Tissue Paper Making Machine Price

this equipment is to perforate and cut the raw paper into various sizes according to the requested.

The finished product is neat, in good order and with equality tension.

It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area of 8.4 m². The highest production speed is 120-160m/min.

This equipment is adjustable to meet the requested finished product. This model is the ideal equipment for paper making factory and paper processing factory. This equipment can process raw paper of 1.75m(75B type) in width. There are two types of this model:

A) is ordinary type, it used one embossed unit for 2 ply paper,

B) other is dot-by-dot type, it used embossed units respectally for each one.

This machine is consist of stand of raw material, paper conveying unit, embossing unit, perforating unit, rolling unit, electricity control and cutting system.

The production process is : unreeling -→ embossing -→perforating-→furl-→slitting

.

|

Machine Model

|

1092

|

1575

|

2000

|

2200

|

2400

|

2600

|

2800

|

||||||

|

Width of Jumbo Roll(mm)

|

1200

|

1800

|

2000

|

2200

|

2400

|

2600

|

2800

|

||||||

|

Production Speed

|

160-240m/min

|

|

|

|

|

|

|

||||||

|

Maximum diameter of rewinding

|

130-250mm

|

|

|

|

|

|

|

||||||

|

Diameter of inner core

|

40-60mm

|

|

|

|

|

|

|

||||||

|

Finished Products Diameter

|

80-120(Thighting can be adjustable)

|

|

|

|

|

|

|

||||||

|

Finished Products Inner Diameter

|

32-60mm

|

|

|

|

|

|

|

||||||

|

Overall Size

|

6200X2750X1800 (LxWxH)

|

|

|

|

|

|

|

||||||

|

Weight

|

About 4.2T

|

|

|

|

|

|

|

||||||

|

Parameter set

|

Touching-screen Multi-menu Man-machine Interface Operation System

|

|

|

|

|

|

|

||||||

|

Controller

|

PLC program

|

|

|

|

|

|

|

||||||

|

Mechanical driving

|

Driven by stepless regulator to guarantee the precise length of final products

|

|

|

|

|

|

|

||||||

|

Air pneumatic system

|

3 Pa (air-compressor), the minimum pressure 5kg/cm2 pa (prepared by buyer)

|

|

|

|

|

|

|

||||||

|

Power

|

4kw-10kw (380V 50Hz)

|

|

|

|

|

|

|

||||||

Chosen items (Should be ordered separately)

|

Embossment

|

Single embossment, Double embossment, Edge embossment

|

|

Embossment down roller

|

Paper roller, rubber roller

|

|

Jumbo roll stander

|

1-3 plies

|

|

Rewinding unit

|

Non-core unit

|

Main Features

1. PLC (computer) control production, degree of full-automatic of production process is high, the function of machine is complete, and production efficiency is high.

2. Load and change the core, spray glue, seal can be done without stop the machine. When changing the core, the machine will low the speed and up the speed automatically.

3. When change the core to rewind, it will be tight first and then loose, to avoid the core loose.

4. Equipped with automatic alarm to indicate filling up of core pipe. The machine will be automatically stopped when there is no core pipes.

5. When raw material broken, the machine will stop automatically.

6. Each raw material unreel separately , equip with tension control.

7. Easy to adjust in order to suitable different paper core.

8. There is tail after the finished product sealed with

9. There is pneumatic jack to load the raw material on machine

As required, the machine can equip with single color or double colors printing device, the pattern is vivid.

The machine can equip with two sets of embossing device according to requirements.

Hot sale

Certifications

Packing & Delivery

|

Packaging

|

|

|

|

Size

|

3200 (L) * 2000 (W) * 1950 (H)

|

|

|

Weight

|

4.2 T

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

FAQ

1.Why buy Machine from

Our Factory

Quanzhou Xinda Machinery Development Co.,Ltd ?

①.

Good quality

of machine with reasonable price.

②.

Good service

: For all the machines we sell, we will offer two-years guaranty for free and all life maintenance.

We deliver a DVD of Operation Video with machine,it will help customer to work the machine easy.

After the machines arrive, the sellers shall send technician to install the production line(if need).

Welcome to contact us to get more details !

We can

design the machine

according to your requirement.

2:How about your machine quality, we are worry about the quality

A:Xinda is a mature brand in China, almost

30 years

manufacturing experience of different kinds of paper machines. We strictly manufacture and manage according to IOS9001:2000 System, and can match all the CE standard or more strict standard. Our paper machine is running well in more

3:How we visit your factory and what will be the procedure?

A:Our factory located in Quanzhou, Fujian province, our nearest airport is JIN JIANG airport, if you take plane, it will need about 1 hours from Guangzhou,1.5hours from shanghai and 2 hours from Beijing. We will pick you up from airport as well as the train station. Welcome you and your team to visit us at any time!

4:Is there any discount of your machine price?

A:Please contact for details.

Send your Inquiry Details in the Below for More information & Video & Specifics of Machine, Click

" Send "

Now

Welcome to contact us to get more details

We can design the machine according to your request.

Hot Searches