NaN / 0

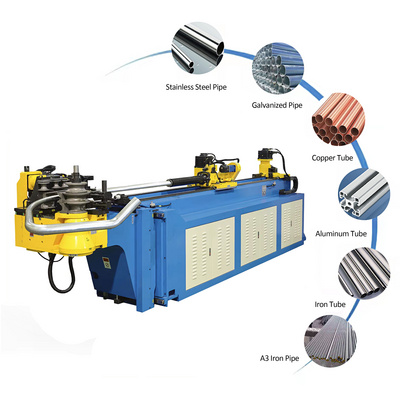

HOT SELL Hydraulic Automatic Tube Bender/Pipe bending machine

Get Latest Price

US$ 5000

≥1 Sets

Quick Details

Bending Radius (mm):

20 - 200

Max. Bending Angle (Deg):

190

Bending Precision (Deg):

0.01

Place of Origin:

China

Product Details

The main parameters of performance and configuration GM SB-38NC

GM-SB-38NC automatically bend in the same machine suitable for continuous automatic workpiece complete different direction, a number of different angles of three-dimensional workpieces, using the touch-screen machine operators and industrial computer control procedures, is an efficient, economical automatic pipe bender.

1. Construction Machine

Body by welding, mechanical parts assembly, import hydraulic system, electronic control of imports of fabric to complete.

2 .Major performances

Using industrial touch screen, in English mode menu is simple, with high precision, fast, multifunctional and high degree of automation. Each action of machine is controlled by PLC programme control system.

3. The technical parameters

Name Unit GM-SB-38NC

Max. Bending Capacity mm 38x2

Bending Radius Region mm 30-200

Bending Angle Region ° 0- 190

Max. Through Effective Distance mm 3000

Bending Precision ° ±0.10

Bending Speed deg/sec 150

Feeding Precision mm ±0.10

Feeding Speed mm/sec 900

Turn Pipe Precision ° ±0.10

Turn Pipe Speed deg/sec 300

Motor Power of Oil Pump System KW 4

Max. Pressure Kgh/cm\2 16

General Length*Width*Height mm 4200x800x1300

General Weight T 2.0

4. Configuration

Packaging & Shipping

|

Name |

Manufacturer |

|

Hydraulic Motor |

Suzhou Runmali |

|

Hydraulic Pump |

Wuxi Tuoli |

|

Hydraulic Valve |

Japan Yuken |

|

Oil way Board |

Suzhou Boguan |

|

Cylinder |

Shanghai Qifan |

|

Oil tube |

Suzhou Kejia |

|

Touch screen |

Taiwan W einview |

|

PLC |

Japan Mitsubishi |

|

Angle controller |

Japan Nemicon |

|

Switch power |

Wenzhou Changxing |

|

Contactor |

German SCHNEIDER |

|

Other Electric Parts |

German SCHNEIDER,Omron , Taiwan SHILIN |

FAQ

1.Q: How to choose the pipe/tube bending machines?

A: You have to inform us following details:

- Max. outside diameter:

- Wall thickness range:

- Bending radius (CLR):

- The pipe material:

- The drawings if possible:

2. Q: What is the difference for NCB, NCBA and CNC machines?

A: NCB is standard hydraulic pipe bending machines, feeding and rotation are manual, and bending is hydraulic automatic.

NCBA is semi-automatic pipe bending machines, mechanical gear feeding, servo motor automatic angle rotation and hydraulic automatic bending.

CNC is fully automatic pipe bending machines, servo motor for feeding and rotations, and hydraulic or servo motor for bending, multiple tooling stack are available for two and more different bending radius (CLR).

4. Q: What is the machine’s control?

A: Standard control is Mitsubishi PLC, Special is IPC controls. IPC with function of 3D view, 3D simulation, DWG readout, remote assistance etc.

5. Q: What is the biggest bending capacity you could offer?

A: As of now the biggest bending capacity is 325mm outside diameter for cold bending. For hot bending, the capacity would be 1450mm.

6. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou city (near to Wuxi).You can fly to Shanghai or Wuxi airport & train station.

7. Q: How is the training and after sales service?

A: Customer is welcome to visit our factory for pre-shipment, and we wil provide trainning service FOC, or we can send our professional engineer to be abraod in customer's plant, and customer will pay for the air tickets, accommodation, meals, and USD100 per day.

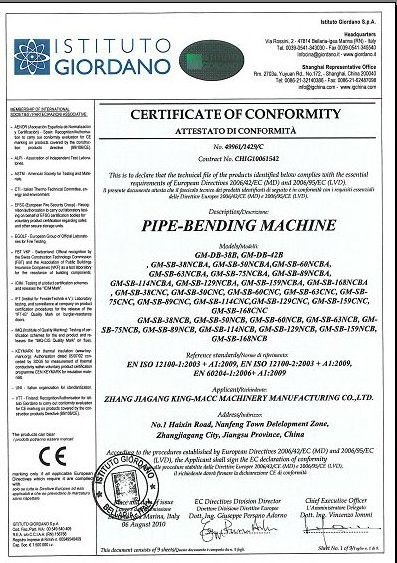

Certifications

Contacts

KING MACC MACHINERY CO., LTD

Add:

No. 1 Haixin Road , Nanfeng Town Development Zone, Zhangjiagang City, Jiangsu, China

Cell phone / Wechat / WhatsApp:

+8618013602501

Skype:

+861

8013602501

www.gmaccbending.com

Hot Searches