Higher Electro-optic conversion efficiency

Superior reliability & modularity

Easy maintenance and low down time

Anti high reflection function

|

Model

|

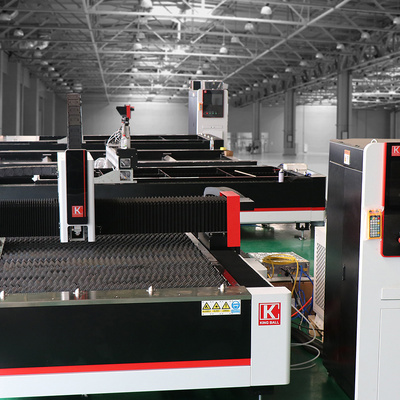

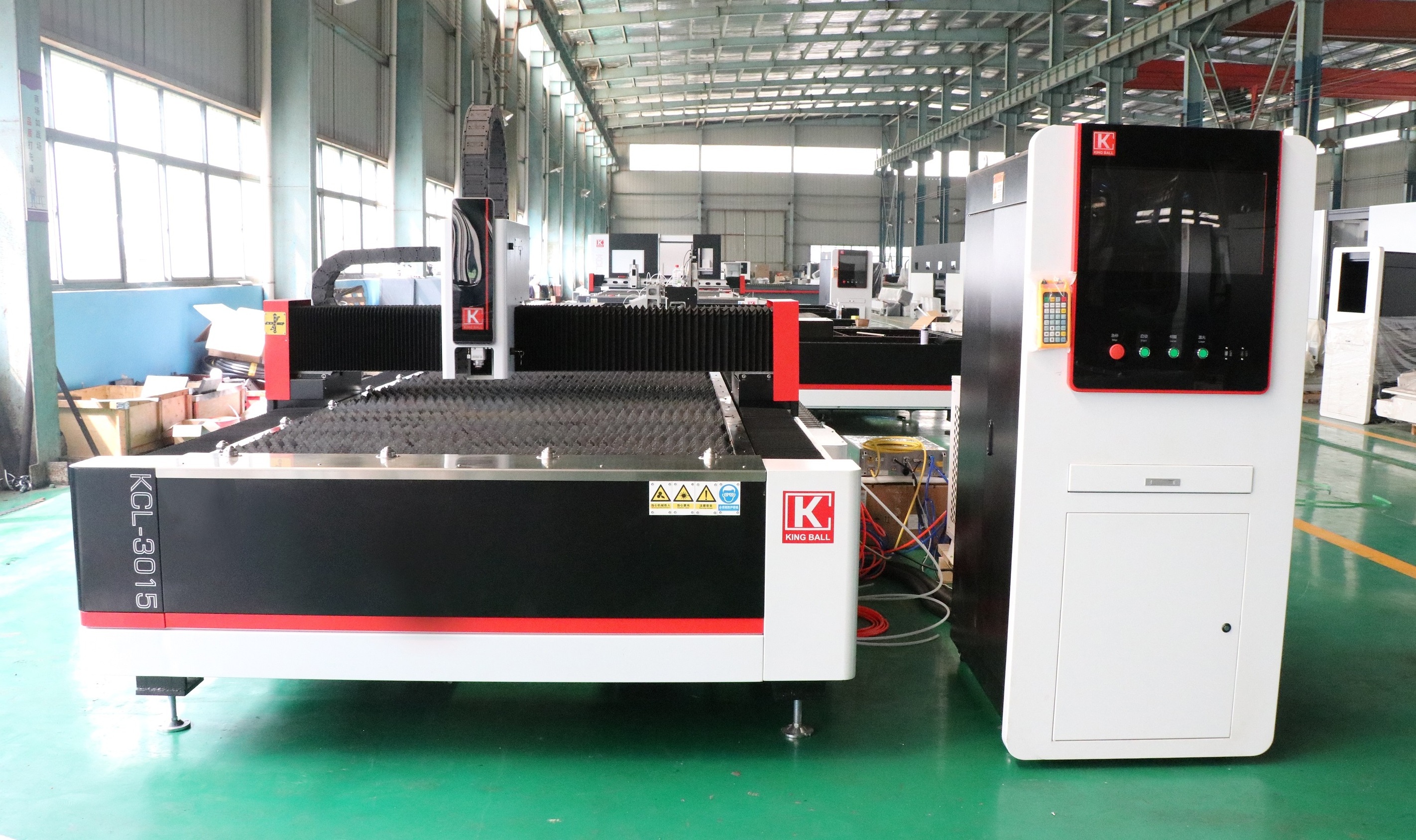

KCL-3015

|

KCL-4015

|

KCL-4020

|

KCL-6020

|

KCL-6025

|

KCL-8025

|

KCL-10025

|

KCL-12025

|

|||||||

|

Cutting Range (mm)

|

3000*1500

|

4000*1500

|

4000*2000

|

6000*2000

|

6000*2500

|

8000*2500

|

10000*2500

|

12000*2500

|

|||||||

|

Laser Power (w)

|

1000W&1500W&2000W&3000W&4000W&6000W&8000W&12000W

|

|

|

|

|

|

|

|

|||||||

|

Maximum idle speed

|

160 m/min

|

|

|

|

|

|

|

|

|||||||

|

Maximum cutting speed

|

35-80 m/min

|

|

|

|

|

|

|

|

|||||||

|

Positioning Accuracy

|

0.03 mm

|

|

|

|

|

|

|

|

|||||||

|

Reposition Accuracy

|

0.02 mm

|

|

|

|

|

|

|

|

|||||||