NaN / 0

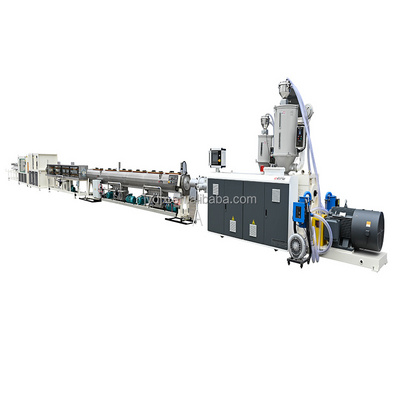

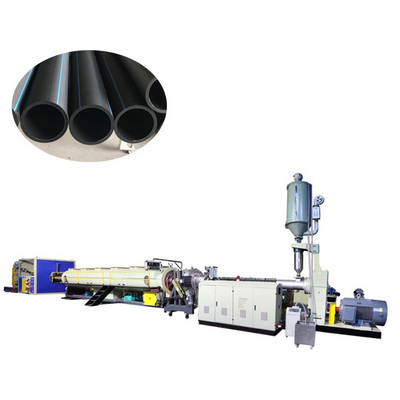

plastic tube extrusion line plastic electric conduit pipe line hose pe hdpe ldpe pp orange pipe machine

Get Latest Price

US$ 50600

≥1 Sets

US$ 46500

≥3 Sets

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

55:1

Screw Material:

W6Mo5Cr4V2 material

Screw diameter (mm):

62.4 mm

Product Details

High Quality PP PE PET PVC ABS Plastic SheetTwin Screw Extruder Machine

Product Description

CTS-H Series Twin Screw Extruder Characteristics:

1.CTS-H series was quipped with import gearbox and safety clutch.

2.The processing section are modular construction design,they have flexible operation in the mixing and extrusion.

3.Their performance are more superior,the quality are more reliable ,compared with foreign high-end products,the extruder have good price advantage and perfect after-sales service.

|

Type

|

D(mm)

|

Do/DI

|

L/D

|

rpm(max)

|

P(kw)

|

T/A3

|

Q(kg/h)

|

|

CTS-40H

|

41.1

|

1.52

|

32~100

|

900

|

90

|

11.6

|

240~400

|

|

CTS-52H

|

51.4

|

1.52

|

32~100

|

900

|

160

|

10.6

|

480~820

|

|

CTS-65H

|

62.4

|

1.54

|

32~72

|

900

|

280

|

10.5

|

820~1500

|

|

CTS-75H

|

71

|

1.51

|

32~72

|

900

|

400

|

11.0

|

900~2300

|

|

CTS-95H

|

93

|

1.52

|

32~72

|

900

|

1000

|

11.1

|

2800~5000

|

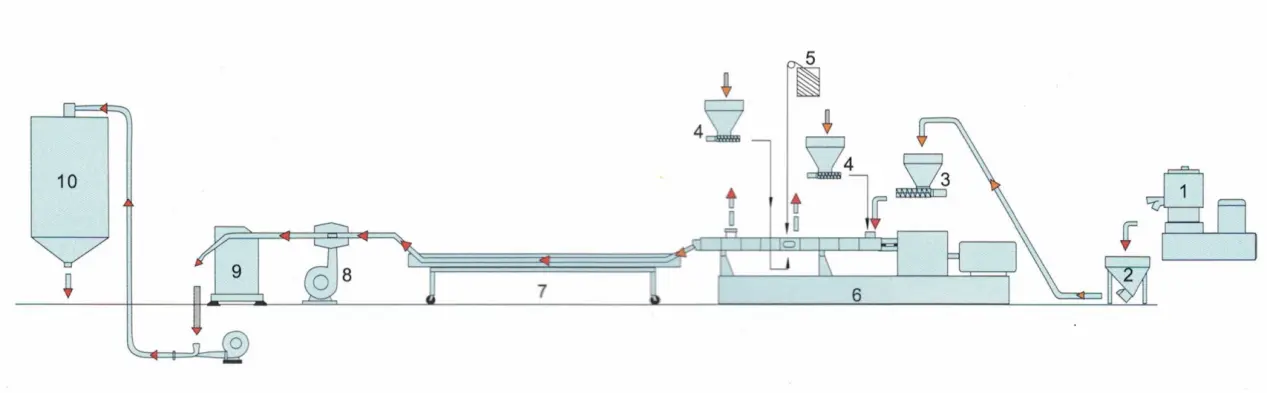

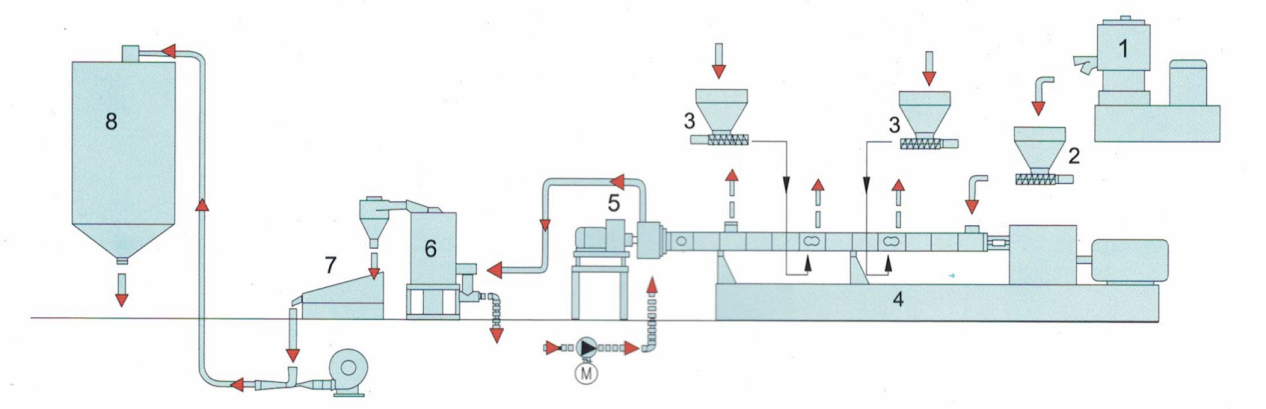

Processing System

1.High speed mixer 2.Spiral conveyer 3. Main Feeder 4.Side feeder

5.

Glass Fibe

r 6.Twin screw extruder

7. Water trough 8.Air-knife 9.Pelletizer 10.Product container

Application:

Reinforced modification: PP, PA, PBT, ABS, AS, PC, POM,PPS, PET, PPO, PSF, LCP add. Glass Fiber; Filling Modification: PE, PP, EVA +CaCo3, talcum powder, titanium dioxide, carbon black; Cable material: LDPE, HDPE, LLDPE, MDPE, sheath material, insulating material; Blend alloy: PC+ABS, PA+ABS,CPE+ABS, PP+EPDM, PA+EPOM, PP+SBS; Color masterbatch: PE, ABS, PS, EVA, PET, PP+pigment, auxiliaries; Flame retardant color mother:PP, PA, ABS, EVA, PBT+ flame retardant, auxiliary agent. Biodegradable masterbatch: PP, PE, PS+starch, auxiliary agent.

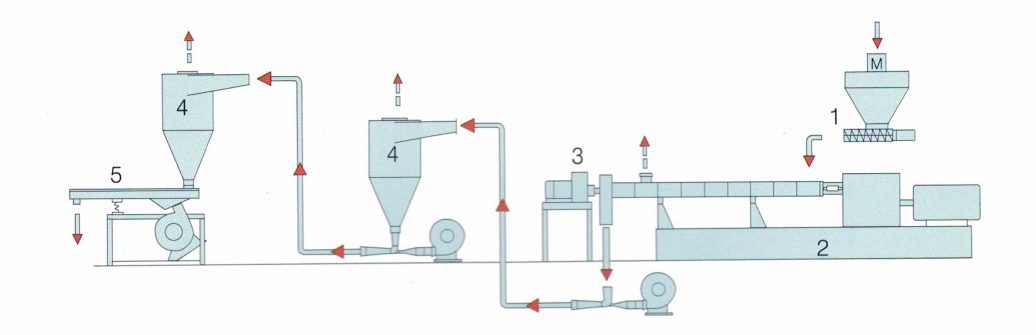

2.Twin screw extruder air-cooling hot face pelletizing production line

1.Metering Feeder 2.Twin screw extruder 3.Air-cooling hot-face pelletizer 4.Cyclone system 5.Vibrating Sieve

Applications:

Enforcing modification: PE, EVA etc.+CaCo3 , Talc, TiO2 , Carbon black;

Biodegradable masterbatch: PE, PS etc. +starch, additive etc; Anti-flame masterbatch: PE, EVA etc. + Sb2O3 , Mg( OH)2, Al2(OH)3 etc.

3.Twin screw extruder water-ring hot face pelletizing production line

1.High speed mixer 2.

Main Feeder 3.

Side feeder 4.

Twin screw extruder 5.

Water-ring pelletizer 6.

Centrifugal dewatering 7.

Vibrating Sieve 8.Product container

Application:

PE, EVA etc. Filled with

CaCO3, talc, TiO2, carbon black etc. Cable sheath, cable insulation compounds of LDPE, HDPE, LLDPE, or MDPE; Radiation-

crosslinkable, heat-shrinkable cable compounds; PPR pipe compounds, PE compounds for crosslinked pipes; TP

R, TPU, TPV thermoplastic

elastomers; EVA and hot-melt adhesives; Color concentrates of PE, ABS, PS, EVA, etc; Flam

e retardant masterbatches of ABS, EVA etc; Masterbatches with PE, PP, PS etc as carriers for degradation applications.

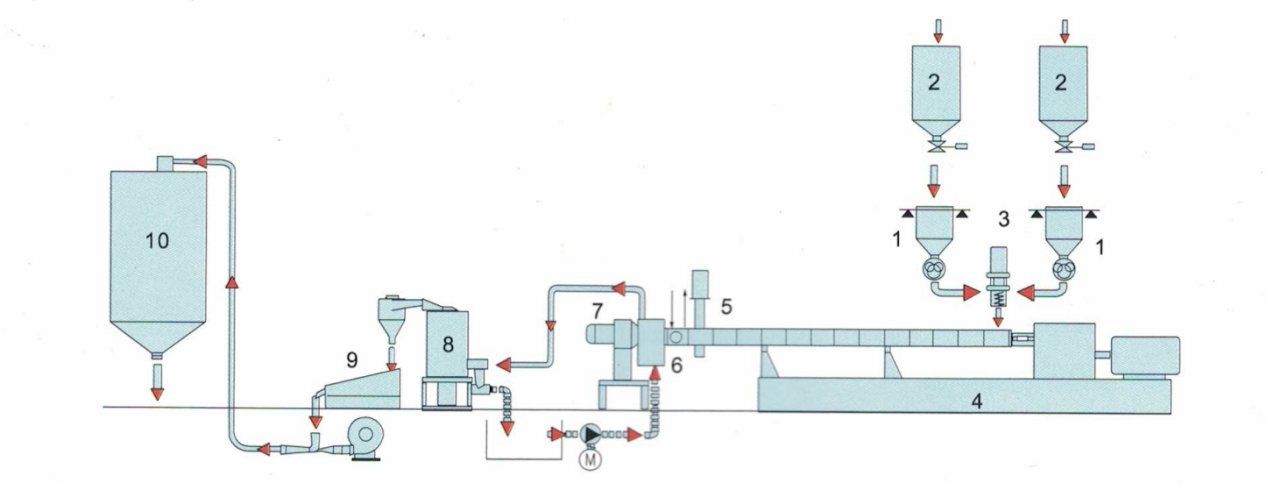

4.Twin screw extruder under water pelletizing production line

1.

Loss-in-weight feeder 2.

Material silo

3.Forced feeding

4.Twin screw extruder

5.

Diverter valve 6.

Screen changer

7.

Underwater pelletizer 8.

Centrifugal dewatering 9.

Vibrating Sieve

10.Product container

Application:

PP, PE and its compounds, various of thermoplastic elastomers, PA, TPU, EVA and other hot melt adhesive.

Extensive heat and mass transfer, narrow residence time distribution, large surface to volume ratio, continuous operation. Ideal for high viscosity, high temperature reaction systems.

Continuous polymerization or reactive extrusion like dynamic vulcanization, crosslinking, grafting, and chain extension of PUR, PA, POM, PEI, PC, PMMA, PBT, PPS, etc.

Products Show

Product Detail

Screw elements

Screw Configuration means a structure composed of different combinations to achieve the desired performance, such as disperse, shear effect, solving the requirements of mixed materials as well as the production stability. Depending on the nature of work being carried out, there are Intake zone, Conveying Zone, Melting Zone, Natural Venting Zone, Mixing Zone, Vacuum Venting Zone and Metering Zone. Different screw elements own different features in different extrusion process, we should choose and design the right screw elements based on different extrusion status in order to optimize the overall comprehensive performance in the extrusion process.

Barrel

Product Description: According to appearance design, it can be divided into close barrel, open barrel and venting barrel. According to the liner, it can be divided into integrated barrel (without liner) and with liner barrel. Diameter: 12-350mm Material: Company adopts imported HIP process of powder high speed steel, and precision CNC machining of the cylinder is adopted to make its accuracy level, wear-resisting and corrosion resistance be consistent with the origin first-line brand abroad; Cost performance is superior to the similar imported products.

Core shaft

Structure: with cooling system/without cooling system Size: diameteter 10-120mm/lenghth 500-9000mm.

(1)40CrNiMo with special treatment and involute form can be used under thecircumstances of high torque, high torsion and high load.

(2 )And nitrogen bearing Martensite stainless steel, WRI5E and WR30 can also be applied to make good toughness and machine. performance available. The performance parameters similar to the imported shaft but with more cost efficient, the machining process is under accurate controlling to make sure the accuracy of groove depth and distance, the smoothness of the surface, toughness and durability as well.

Our Company

Factory

Workshop

Warehouse

Team

About us:

Nanjing Beyou Extrusion Machinery Co.,Ltd. is a professional rubber and plastic machinery manufacturer, mainly engaged in plastic extrusion machine as the core of the plastic modification equipment and related technology and engineering field of research and development and production of auxiliary machines. The main products are twin-screw extruder, single-screw extruder, PVB intermediate film production line equipment, glass fiber reinforced thermoplastics production line and self-developed underwater granulation system, which are widely used in various kinds of plastic and rubber materials, such as coloring, blending, filling, strengthening, stripping and recycling. According to different requirements of customers, we can provide appropriate solutions for customers.

Our company leads the industry in either software or hardware. Now it has a high-quality R&D team and engineering team that have engaged in the field of twin-screw extruder for many years. We have equipped with standard workshops, various automated advanced processing equipment and modern quality testing center. Our company invests huge sums of money in R&D every year to cooperates customer's development requirements, and dedicated to provide customers with technical design, machine assembly and on-site debugging services, strive to create greater economic and social benefits for customers.

Customer Photo

Packing & Delivery

Packing Details: Wood cases or sea worthy packing.

Delivery Details: Within 8 weeks from the receipt of your down payment.

Our Service

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: Can you see the running machine in our factory?

A: Yes.Before making your decision buying the equipment or not, you can bringsome material here to test-run the equipment.

Q: How much does it cost?

A: Please fill in your specific requirement in the bottom blank and sent to us, so that we could make a detail quotation for you.

Q: How to get to our factory?

A: (1)You can get to the lukou airport directly, then, connecting us and we will pick you up by car. (2)You can take the train to nanjing south station, then, taking the subway to get to China Pharmaceutical University Station, we will pick you up by car.

If you have another question, pls feel free to contact us as below:

Nanjing Beyou Extrusion Machinery Co.,Ltd

NO. 227 Zhening East Road, Lishui District,Nanjing

Mobile Phone/wechat/whatsapp: +8619951799288

Tel.: 025-52289830 I Fax: 025-52289833

NO. 227 Zhening East Road, Lishui District,Nanjing

Mobile Phone/wechat/whatsapp: +8619951799288

Tel.: 025-52289830 I Fax: 025-52289833

E-mail: sunny@njbeyou.com

Hot Searches