NaN / 0

OEM\ODM Plastic Tub Thermoforming Vacuum Forming Aluminum Large Plastic Large Bath Tub Free Standing

Get Latest Price

US$ 15

≥100 Pieces

US$ 12

≥150 Pieces

Quick Details

Processing Service:

Moulding, Cutting

Place of Origin:

Guangdong, China

Brand Name:

Ditai

Model Number:

Ditai

Product Details

Product Details

Thermoforming process can make lots of trays, it is one kind of simple products for our process, but if you want to make the trays durable, and meet your expectations, then we will need to consider the material selection, So what material is suitable for the plastic tray, this answer varies according to the field in which the tray is used, For example, we will suggest cold-resistant material for

refrigerant tray, food grade material for planting tray, will provide high impact material for those heavy trays and so on, No

worries about that if you don’t know how to choose the material, our plastic expert will help you with this;

refrigerant tray, food grade material for planting tray, will provide high impact material for those heavy trays and so on, No

worries about that if you don’t know how to choose the material, our plastic expert will help you with this;

|

Available Material

|

ABS, PS, HDPE, PC, PETG, PVC, etc

|

|

Color

|

For your selection

|

|

Coloring style

|

Spray painting or Silkscreen or The material color

|

|

Surface Effect

|

Smooth, Matt finish, Texture

|

|

Logo

|

Customized

|

|

Max Size

|

4000*2000*1000mm

|

Material Suggest For You

When choosing a plastic, you'll need to consider its application. Will your product be used inside or outside? Will it be exposed to extreme heat or cold? Does the product need to withstand high impact? Are you looking for something that's fire retardant? As a general rule of thumb, we work to the following guidelines.

The following chart provides additional information about various plastic materials and their uses.

The following chart provides additional information about various plastic materials and their uses.

|

Plastic Material

|

Advantage

|

Industry example

|

|

ABS (Acrylonitrile Butadiene Styrene)

|

ABS has very good mechanical properties, dimensional stability, processing ability, chemical resistance, and a high-quality

appearance

|

It has been widely used in manufacturing machinery, electronic components, electrical and home appliances, auto parts, medical

products, food and water contact materials, construction materials, toys and sporting goods, and cosmetics containers.

|

|

ASA

|

ASA is a copolymerization of styrene, acrylonitrile, and acrylic rubber. Technically, ASA not only maintained the main

characteristics of the ABS, it also combines the weather resistance advantage of acrylic to extend the product application for

outdoor purposes.

weather resistance durability, color stability, and good PC/PVC capability

|

Can be applied in automotive parts, construction parts, outdoor sporting goods, gardening parts, outdoor antenna parts, electronic

and electrical products, toiletries, etc. In addition,ASA also reduces the secondary coating and electroplating processing costs,

allowing its products to have cost reducing and environmental friendly features.

|

|

PS(Polystyrene)

|

PS resin is a solid polymer formed by heat polymerization of styrene . High Impact Polystyrene (HIPS) composed of SM and butadiene

(BD). HIPS is high impact resistant and non-transparent

|

Suitable for home appliances, food and water contact materials, toys, and construction materials, and especially appliance

housings due to its excellent processability

|

|

PMMA

|

PMMA resin is a polymer mainly composed of methacrylate (MMA). It features high cleanliness, crystal-clear transparency, and high

gloss, earning it the nick-name Plastic Queen for its excellent appearance. It also delivers stable physical, chemical, optical,

and electrical properties.

|

Widely used in the applica-tion of electronic panels, mechanical parts, surfaces of watches and clocks, vehicle lights,

telecommunication equipment, insulation parts, and sunglasses, food and water contact materials, cosmetics containers, and toys

|

|

Polycarbonate

|

This resin offers glass-like transparency, high heat resistance, ultra high impact resistance, and dimensional stability, making

it suitable for a wide range of applications. It is also compatible with other materials such as ABS and PET, creating diverse

alloy products

|

Suitable for ethylene oxide and gamma ray disinfection, and can be applied in medical equipment. This material is also suitable

for all 3C products, precision machinery, instrument products, automotive parts, sporting goods, sanitary hygiene products, and

food and water contact materials.

|

|

Polycarbonate/ABS

|

Balances the properties of polycarbonate (PC) and acryloni-trile-butadiene-styrene copolymer (ABS). The PC component provides high

heat resistance, high impact resistance, non-halogen flame retardancy, and high rigidity and tensile strength properties. The ABS

component gives better processability, higher impact strength in low temperature envi-ronments, and the ability to be

electroplated,dimensional stability, and a high-quality appear-ance

|

This material effectively reduces the visible signs of injection, provides a wider range of injection conditions, and improves

the maintenance rate for related equipment. Suitable applications range across transportation, networking, 3C electronics

products, TV sets, home appliances, and toys and sporting goods.

|

|

PETG (polyethyleneterephthalate)

|

Very easy to process, high clarity -good for transparent parts,UV protection,high impact,Excellent chemical resistnace

|

It is widely used in indoor and outroor signage,storage shelves,vending machine panels,furniture,construction and mechanical

baffles.

|

|

PE

|

heat resistant, and cold resistance,High impact,chemical stability

|

It is widely used in Arena board, bulletproof board, bottle cap, chemical corrosion-resistant pipeline system, car fuel tank, food

storage container, safety helmet

|

Aluminum Mold Production

Our mold engineers will convert the 3D drawing into mold drawing, and select the right type of aluminum according to product characteristics for mold engraving.

After engraving, we will make air holes and polish the mold surface to avoid negative impacts on the product surface.

We can ensure that the mold is never-ending use, even if the loss and damage, we will be free re-mold.

Extrusion Plastic Sheets

Ditai owned two extrusion-forming machines. The raw materials are extruded and formed through the machines, which enables the plastic sheet materials to have excellent mechanical properties.

The excellent impact strength allows them to be used at extremely low temperatures. And the texture is exquisite, as well as more solid and durable.

Customized material with different properties according to customers' requirements, such as flame retardant, UV resistant, corrosion resistant, color, impact resistant, texture, etc.

Vacuum Forming

Ditai has 16 sets of large plastic vacuum forming machines, reaching 4000*2000mm, which is currently the giant machine in Guangdong. One of the full-auto machines is designed by the General Manager of Ditai.

The vacuum forming method is divided into positive molding forming and negative molding forming. Depending on the characteristics and requirements of the product.

Sometimes we will use an upper mold or auxiliary molding tools to help better molding in place. For some polyhedral products or some with a right-angle surface and a small draft angle, we will use bulge technology.

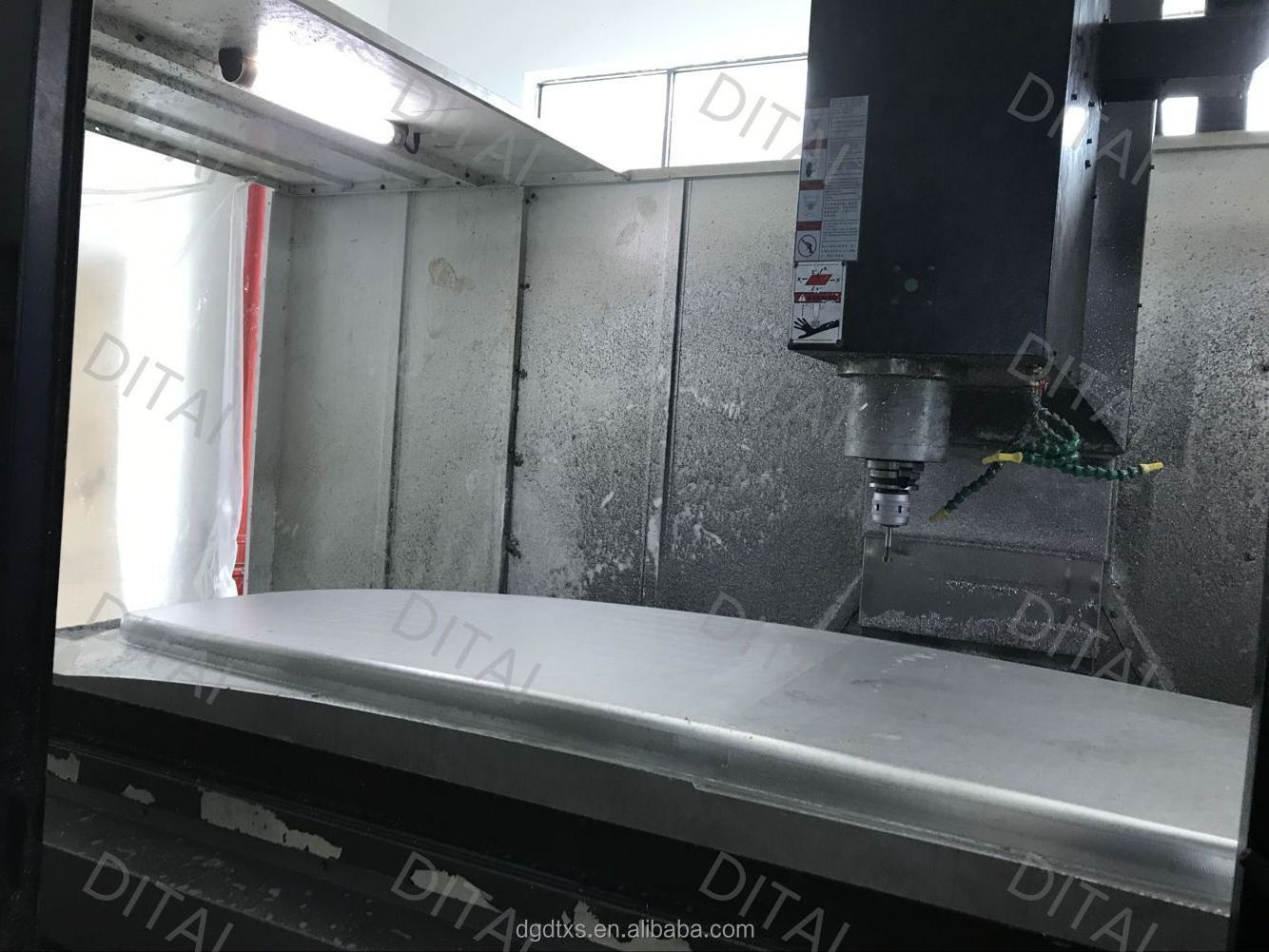

CNC Cutting

Ditai has 28 CNC cutting machines, which has one of the largest numbers of CNCs in the thermoforming field in China. In the first beginning, our engineer will convert 3D drawings into drawings suitable for CNC cutting, and then he will make the corresponding mold according to the shape of the product.

How you want the product shape most accurately cutting of? First of all, our CNC machines are 5-axis robot hands, which can process 360 degrees in all direction and is fast. And will make a wooden jig with small air holes which according to the shape of the products.

Then insert the magnets into the jig, on the other side of the magnet is placed on the product surface to make it match with the jig tightly, the small vacuum holes on the wooden jigs will pump out the air between the product and mold so that there is a vacuum state between them. These two steps make our products fit perfectly with the jig.

Assembly/Gluing and Spray Painting/Silkscreen and Packaging

For products with high requirements on the surface, we can meet the high requirements of customers, so our products can be widely used in various industries. We also have a special painting department to ensure we can paint the product the way our customer wants.

Ditai owned a paint department and we can provide professional processing, like bonding, polishing, silk screening, printing, spraying, etc. We can also meet the painting requirements such as UV resistant paint, high strength paint, anti-scratch paint, frosted look, high gloss automotive paint, etc.

Will paste a film on the surface of each product to avoid scratches during transportation. Or paste the film on all the surfaces according to your needs for the product. This film will be attached to the sheet from the time it is made until it's shipped to your address.

Some Plastic Tray