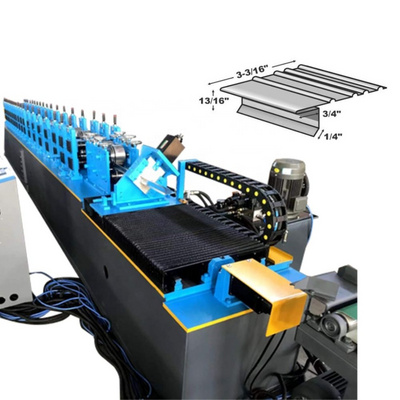

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 1220mm

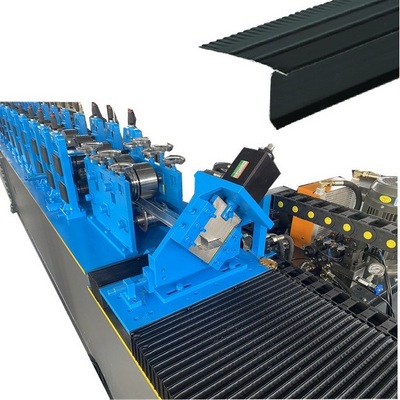

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine