NaN / 0

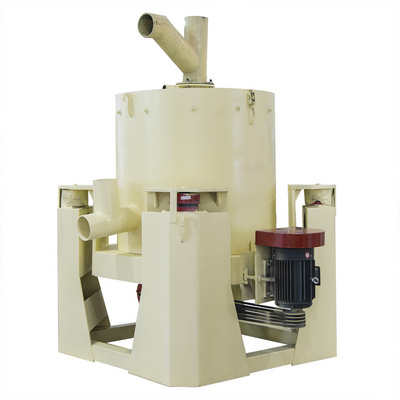

Sino Mineral Separating Knelson Centrifugal Gold Concentrator

Get Latest Price

US$ 4600

≥1 Sets

US$ 4200

≥5 Sets

Quick Details

Production Capacity:

98%, 98%

Place of Origin:

Henan, China

Brand Name:

Sino Mining CO.,LTD

Voltage:

380V, 380V

Product Details

| Sino Mineral Separating Knelson Centrifugal Gold Concentrator |

STL Gold centrifugal concentrator processing plant is a kind of centrifugal concentration equipment. It can be used not only for placer gold mining but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the old tailing.

Application shows that the recovery can be as high as 90%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of 0. 074mm, the recovery for the natural gold is expected up to 98%, For that natural gold of 0.004mm in particle size, the recovery is 97%. The cleaning upcycle is 1~4 hours, and the upgrade ratio is up to 1,000 times. The equipment is patented in China.

Centrifugal concentrator working principle:

The main shaft is a hollow shaft, the pressurize backwash water comes from the shaft, then goes into the separation unit, the water spray from holes to the gratings. During the process, the pressure of the water shall be 0.06-0.15MPa.

The slurry which is mixed with water and ore and sand will be injected to the mainframe. With the heavy centrifugal force, the slurry will be moved upward along the cone body, the light particles will be extracted from the upper part of the cone, then discharge through the tailing outlet. The heavy particles will be staying in the gratings of the inner layer.

Features of The Nile gold centrifugal concentrator :

1. High concentrating ratio and high recovery;

2. Total process automation, steady recovery performance;

4. Environmentally friendly ( no chemical additives or reagents);

5. Low water and electricity requirements;

6. Low production costs, durable wear parts, minimal maintenances requirements;

7. Compact design requiring less space, easy merged into the existing mining processing;

8. Quick payback on investment, typically less than a half-year.

Technical Parameters

|

Model |

Capacity (t/h) |

Power (kw) |

Feed size (mm) |

Slurry density (%) |

Backlash water quantity (kg/time) |

Concentrates capacity (kg/time) |

Cone rotation speed (r/min) |

Water pressure (mpa) |

Weight (t) |

|

STL-30 |

3-5 |

3 |

0-4 |

0-50 |

6-8 |

10-20 |

600 |

0.05 |

0.5 |

|

STL-60 |

15-30 |

7.5 |

0-5 |

0-50 |

15-30 |

30-40 |

460 |

0.16 |

1.3 |

|

STL-80 |

40-60 |

11 |

0-5 |

0-50 |

25-35 |

60-70 |

400 |

0.18 |

1.8 |

|

STL-100 |

80-100 |

18.5 |

0-6 |

0-50 |

50-70 |

70-80 |

360 |

0.2 |

2.8 |

Package&shipment

Products Site

About Us

Our Services

Pre-sales service: We provide you with prophase plan, process flow design and manufacturer equipment according to your special needs.

Sales service:

Send technicians to your site guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sales service:

To establish long term friendship, we will pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

Lifelong service:

One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

FAQ

Q1: Are you factory or trade company?

A1: We are factory.

Q2: Where your products have been exported before?

A2: Our products have been sold to South Asia, Africa, South America, middle East and so on.

Q3: How will you help the customer to install the equipment?

A3: Our senior engineer will guide the installation and commissioning as well as the initial production at

Q4: How about the wear parts supply?

A4: We offer wear parts to our customer with our most favorable price. If there are problems youcould not handle, we will send our technicians to your place and you are therefore, responsible for all thecost involved.

Q5: What about the payment method?

A5:T/T, L/C Paypal is available

Q6: What about after-sale service?

A6:12 months warranty for all kinds of products.

Hot Searches