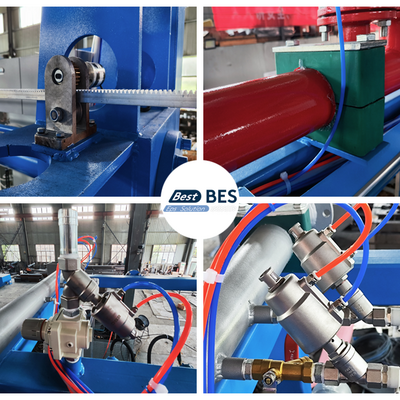

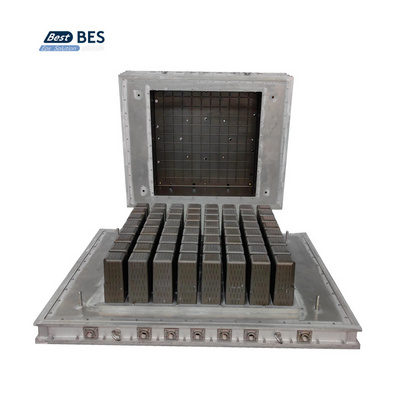

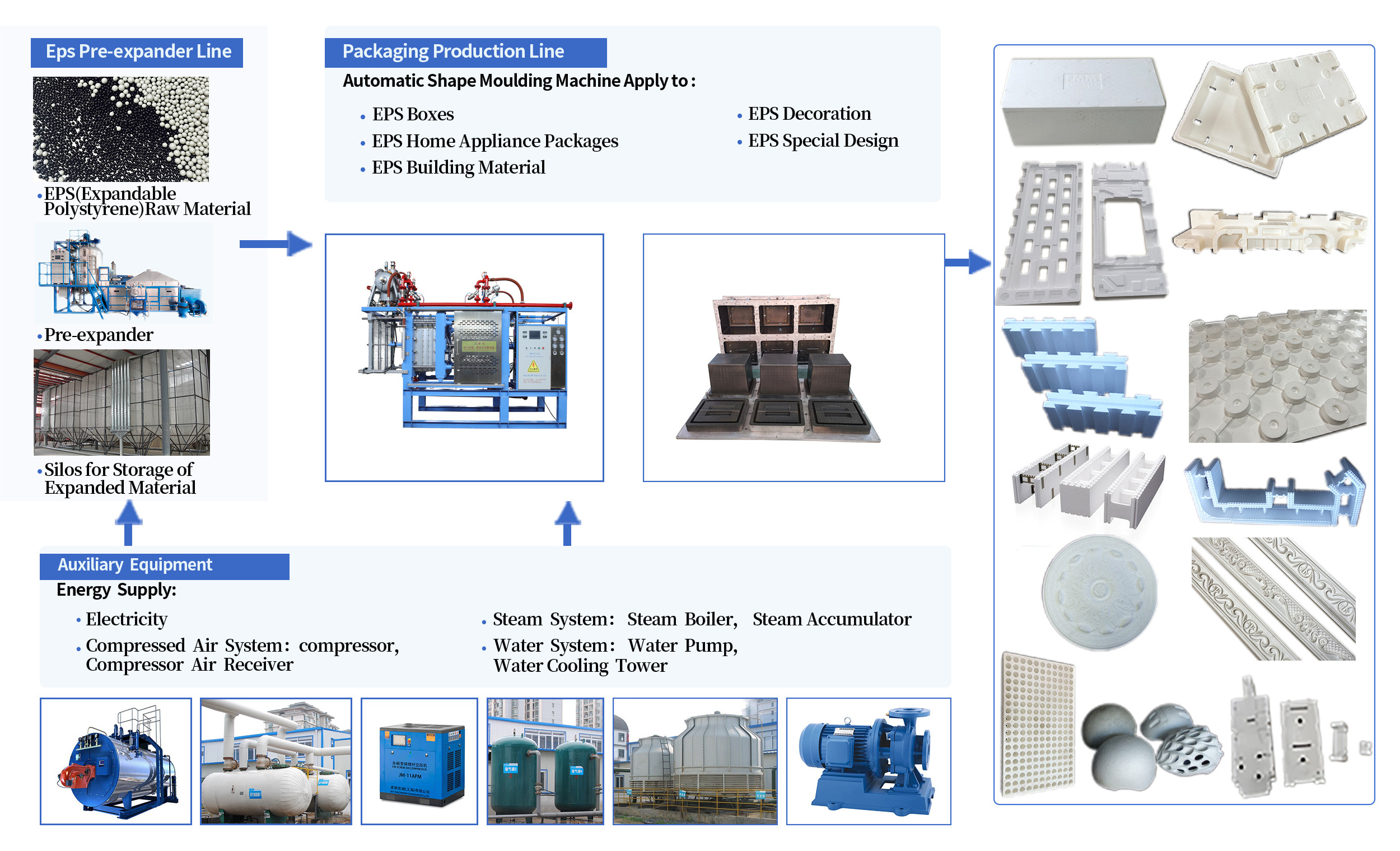

EPS Shape Moulding machine is defined as a process manufacturing EPS formed products such as EPS packages or insulation materials by the moulds are filled with expanded EPS beads by means of pneumatic filling injectors, pressure filling systems, shaped by steam heating in the closed state with the aid of a vacuum.

EPS foam products have wide application fields in heat insulation, food and electronics packaging and building decorates terms and

so on.