NaN / 0

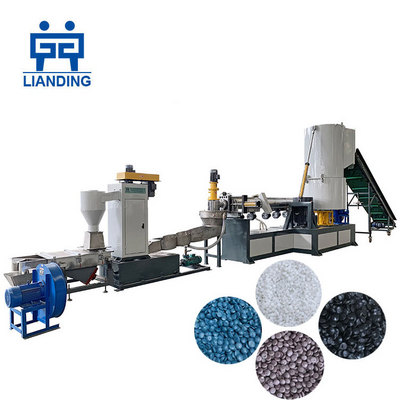

PP PE film single screw shaft waste scrap plastic recycle granulating line plastic compactor granulator machine

Get Latest Price

US$ 90000

≥1 Pieces

US$ 50000

≥3 Pieces

Quick Details

Output (kg/h):

150 - 1000 kg/h

Place of Origin:

jiangsu

Brand Name:

boxin

Voltage:

380

Product Details

Welcome to BOXIN

Product Description

01. Belt conveyor

Belt conveyor : PVC material

Metal detector is optional to prevent metal materials from entering the extruder with raw materials (film)

02. Compactor

Double layer cutting disc, more efficient feeding and 10% - 20% increase in output

Hydraulic opening and hydraulic lifting, safe and easy to maintain .

03. Single Screw Extruder

Screw and barrel : 38CrMoAl, nitriding treatment

Heater : Ceramic + stainless steel cover

Vacuum pump exhaust, double exhaust

04. Water Ring Cutting Machine

Die head material : 38CrMoAlA

Material of water ring cover : stainless steel 304

Horizontal design with linear guide rail, easy operation and maintenance

Pneumatic adjustment makes the cutting blade in soft contact with the die surface, so as to achieve 100% contact between the blade and the die head and avoid die surface damage.

05. Vibrating Dehydrator

The linear vibrating screen uses the vibrating motor as the vibration source to make the pellets throw on the screen and move forward in a straight line. Several sizes of sieves are available for discharging from their respective outlets.

Line screen fully enclosed structure, no dust and overflow, automatic discharge, etc., more suitable for 24 hour assembly line operation

Low energy consumption, high output, simple structure and easy maintenance

Combination of filtration and dehydration, high efficiency and power saving

06. Two Stage Granulator (Optional)

One stage granulator, two stage granulator which we are all supply

|

Model

|

BXC2-85

|

BXC2-100

|

BXC2-120

|

BXC2-150

|

BXC2-160

|

BXC2-180

|

|

Capacity(KG/H)

|

100-200

|

200-300

|

300-400

|

500-600

|

700-800

|

800-1000

|

|

L/D

|

1:33

|

1:33

|

1:33

|

1:36

|

1:36

|

1:36

|

|

Install Power(KW)

|

110

|

135

|

160

|

310

|

370

|

520

|

|

Compactor Power(KW)

|

37

|

45

|

55

|

110

|

132

|

185

|

|

Main extruder Power(KW)

|

55

|

75

|

90-110

|

185

|

220

|

280-315

|

|

Screen exchanger

|

160mm

|

200mm

|

250mm

|

350mm

|

400mm

|

3000cm*2

|

|

Staff requirement

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

|

Overall size(L*W*H)

|

9*5*4

|

10*5*4

|

12*5*4

|

13*6*4

|

13*6*4

|

13*6*4

|

Recommend Products

Hot Searches