NaN / 0

multi-functional Ultrasonic Extractor Machine/herbs Extraction Machine/ ultrasonic plant Oil Extractor

Get Latest Price

US$ 35000

≥1 Pieces

Quick Details

Place of Origin:

Shanghai, China

Brand Name:

Juyuan

Model Number:

JY-ST200

Weight (KG):

260

Product Details

multi-functional Ultrasonic Extractor Machine/herbs Extraction Machine/ ultrasonic plant Oil Extractor

Brief introduction of Equipment Features:

1. High efficiency of the equipment: This equipment is the latest small Soxhlet extraction unit jointly developed by our company and the Murad Modern Research Center of the University of Chinese. This equipment organically combines Soxhlet extraction with Soxhlet hot reflux extraction. The working efficiency is twice that of the ordinary Soxhlet heat reflux extraction unit.

2. Strong equipment durability: Soxhlet extraction process is a classic process for the preparation of traditional Chinese herb. This equipment combines years of experience in the use of ordinary glass Soxhlet extractors from the Murad Modern Research Center , Shanghai University of Traditional Chinese , and combines our factory's exquisite production technology to develop an all-stainless steel (SUS304 2B) high-efficiency automatic Soxhlet Extract the unit. Each part of the equipment is durable, easy to clean, and easy to operate.

3. The extracted liquid herb is of high quality: the Soxhlet extraction unit in this equipment can be vacuum extracted, effectively reducing the loss of heat-sensitive active ingredients. At the same time, avoid the dissolution of vegetable protein from the material into the liquid herb due to high temperature extraction, which will affect the quality of the liquid. At the same time, the Soxhlet extraction unit is equipped with a stirrer, so that the Chinese herb materials can fully contact the solvent, and accelerate the precipitation of the active ingredients in the raw material.

4. Taking into account the convenience of taking herb slag, the extraction part of the equipment is equipped with a large-diameter manhole or hand hole, and is equipped with a double filter system to prevent fine slag from flowing into the material storage tank. The connecting pipeline is equipped with a glass sight glass, which can observe the appearance of the extraction liquid at any time.

5. The structure of the equipment is compact and firm: because the concentration tank is an independent unit, the tank structure is compact, the tank body is a three-layer insulation belt heated arc structure, and the internal interlayer is supported by a high-strength Miller board. It can work at a lower temperature under negative pressure vacuum, so that the thermally sensitive active ingredients in the material can be retained to the greatest extent. This can better ensure the concentrated quality of the liquid.

6. High conversion rate of raw materials: Because the evaporation chamber works at a lower temperature during the concentration process, the heat-sensitive active ingredients in the materials are retained to the greatest extent. This can better ensure the concentration effect of the material.

7. The equipment temperature control is sensitive: the equipment temperature adjustment is very sensitive (accuracy ±1°), the heater can quickly reflect the operation instructions, such as the use of touch screen PLC control, you can also set the Soxhlet display level, stirring speed, heating Process parameter information such as the temperature of the device and the temperature of the material in the tank.

8. The equipment has a compact structure and a small site area. The actual area is about 5M2. It can be equipped with movable casters for easy operation.

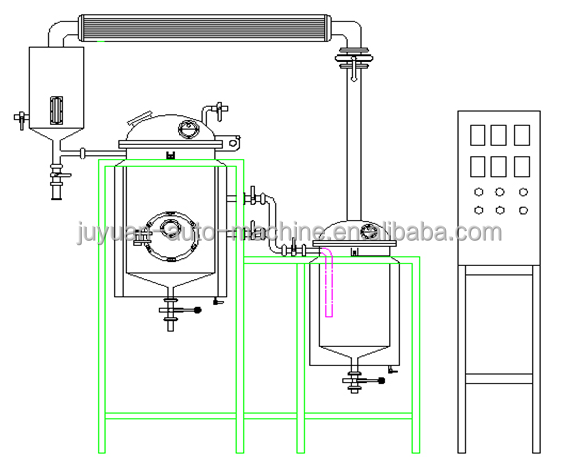

Main Equipment Composition

|

1. Cooler 2. extraction tank 3. Explosion-proof stirring motor 4. Water ring vacuum pump |

5. Hot water generator 6. Tube condenser 7. Coil cooler 8. Filter |

9. Stainless steel frame platform,

10. Matching connecting pipeline, lighted sight glass, sanitary valve, Fuji digital display temperature sensor, Schneider Electric.

a. Configuration list

|

No. |

Part Name |

Model or Specification |

Remark |

|

1 |

Extraction Tank |

300L |

SUS304 |

|

2 |

Vacuum Concentration Tank |

300L |

SUS304 |

|

3 |

Condenser |

2.5M 2 |

Tubular type |

|

4 |

Cooler |

1.35M 2 |

Coil pipe |

|

5 |

Vacuum Pump |

5.5KW |

Water circulation type |

|

6 |

Tube filter |

SUS 304 |

60mesh~200mesh for choice |

|

7 |

Miniature Superhot Water Generator |

Stainless steel Heater |

Jacket type heating |

|

8 |

Temperature Control System |

Digital temperature controller |

|

|

9 |

Manual Valves |

Butterfly valve, and ball valves |

|

|

10 |

Temperature Control Modular |

Fiji temperature control |

|

|

11 |

Electric control box |

Stainless steel material |

|

Hot Searches