NaN / 0

New design teak wood solid feeling engineered timber flooring

Get Latest Price

US$ 22

≥2000 Square meters

US$ 17

≥20000 Square meters

Quick Details

After-sale Service:

Online technical support

Project Solution Capability:

graphic design

Application:

Supermarket

Design Style:

Traditional

Product Details

|

Engineer Flooring:Poduct Attributes |

We have products of Engineer flooring with different specification for your choice.

| Color | We have several hundreds of color for your choice. |

| Thickness | 7mm, 8mm, 10mm, 12mm, 15mm are available. |

| TOP Layer Species | Teak, Oak, Hickory,Birch,Walnut, Beech, Acacia, Cherry, Mahogany, Maple, Merbau, Wenge, Pine, Rosewood etc. |

| Surface treatment | More than 20 kinds of surface, such as embossed, crystal, EIR, handscraped, wavy embossed, matt, mirror, silk etc. |

| Edge treatment | V-Groove with painting, bevel painting, waxing, padding, press etc. are provided. |

| Special treatment | Waterproof wax seal, soundproof EVA |

| Surface size | Hundreds kinds of size to satisfy you. Customized design is acceptable. |

| Wear Resistance | AC1,AC2, AC3,AC4, AC5 standard EN13329 |

| Base materials | Plywood Core/HDF |

| Click system | Valinge 2G, T&G |

| Installation Method | Floating |

| Formaldehyde Emission | E1<=1.5mg/L, or E0<=0.5mg/L |

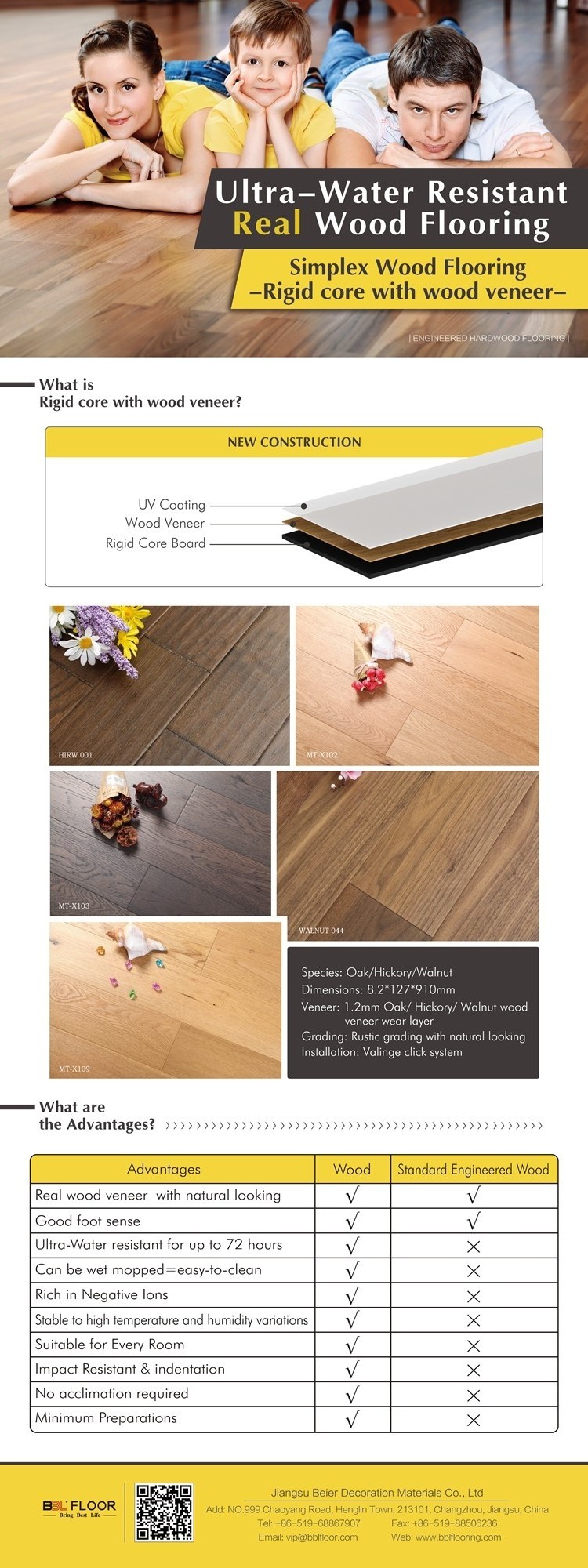

| Structure | Veneer+plywood base |

|

Product Description |

Engineered Flooring lets you bring the beauty and warmth of hardwood into all areas of your home.It looks like solid hardwood because it is !But underneath, it's "engineered" to allow the wood to naturally contract and expand .That means it can be installed virtually everywhere,even in high-moisture areas like basements and over concrete!

European Oak is one of our best selling products, which also gains the most popularity among each country.

Hardwood is truly classic. Natural and charming, the richness of wood flooring adds warmth to any room. Varying in durability, grain patterns, textures, and color, your options can seem limitless.

Aside from its beauty, quality and durability, this type of home flooring is considered a great investment because it increases the value of a home by bringing warmth into each room as well as the ease of cleaning.

|

BBL Research Institute |

|

Engineered Floor : Base Material (Two Types for choose) |

|

Click types |

|

|

|

T & G (More suitable for Plywood core) Tongue and groove is the traditional method to fit flooring. The planks of flooring have one long side and one short side with a tongue (machined protruding edge) and one long side and one short side with a groove (machined rebated edge). When fitted together the tongue should fit into the groove perfectly creating smooth, gapless flooring. The floor can either be secret nailed, secret screwed or glued directly down to the subfloor, or can be floated over an underlay by gluing along the length and width of the plank and pushing them together. Tongue and groove flooring is available in both soild and engineered wood, so can be fitted on any subfloor that has been well prepared. The down side of tongue and groove flooring is that it can be quite challenging to install and may need a professional wooden floor fitter to ensure the floor is correctly installed and to obtain minimum wastage. |

Apart from engineered wood flooring, we also produce vinyl flooring, vinyl composite flooring (so-called WPC flooring), super hybrid flooring and laminate flooring.

| Superior Products |

|

|