NaN / 0

Metal mesh speaker grill punching net making machine

Get Latest Price

US$ 22500

≥1 Sets

US$ 22000

≥2 Sets

Quick Details

Wire Diameter (mm):

0.2 - 6 mm

Marketing Type:

New products

Production Capacity:

80stock/min

Place of Origin:

HEB

Product Details

punching mc

Metal mesh speaker grill punching net making machine

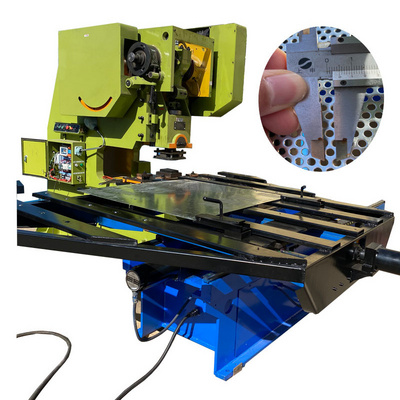

I. Technical parameter

v Pounding plate: 1.25*2.50m

v Pounding thickness: 0.1-6mm

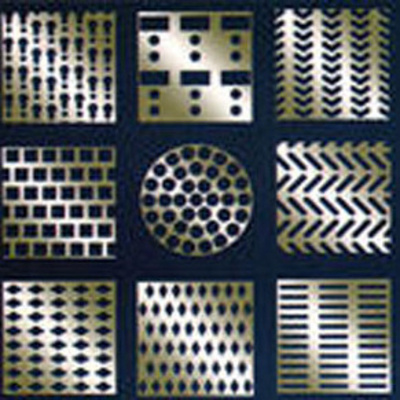

v Mesh size: according the mold, ( mold price: USD1000)

v Times of pounding:60-90/min

v Pressure: 250KN

v Power: 7.5KW

v Space requirement: 6*3m Weight: 8T

v Parts including: pressure machine, feeding system, control system

v Operation: computer control, software: Chinese--English

II. Other instruction about the machine and service

· Ø The warranty time: one year ( accessory parts)

· Ø Material of mould: tungsten steel or Cr12

· Ø Worker needed: one worker can operated two or three sets machine

· Ø All the accessory parts is GB national standard

· Ø The mould is manufacture according the customer's requested.

III. Detail for the pressure machine:

| model | SHP25 | |

| Capacity | KN | 250 |

| Norminal force | mm | 4.0 |

| slide stock | mm | 80 |

| stock times | /min | 60 |

| Max. die height | mm | 180 |

| Die height adjustment | mm | 70 |

| motor power | KW | 2.2 |

| outside size | mm | 1790*990*2288 |

Usage

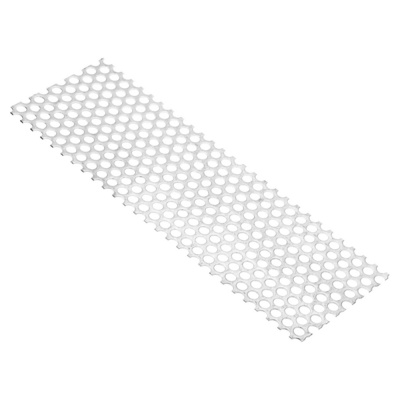

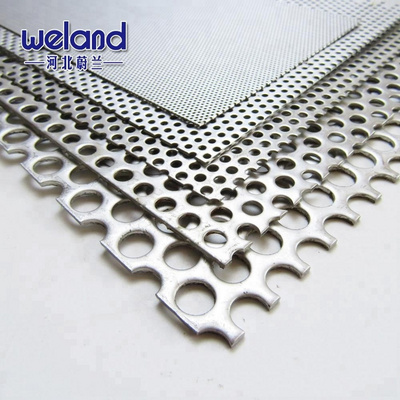

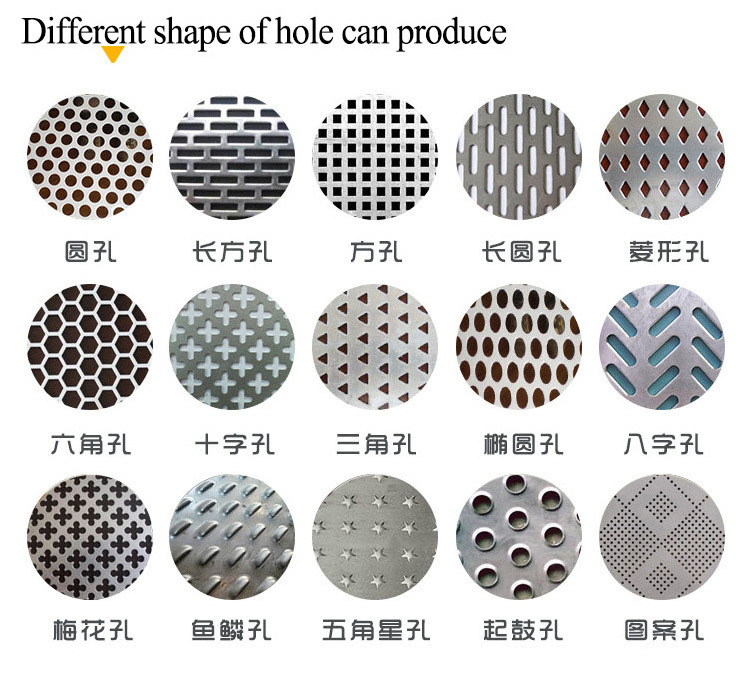

This machine can produce different shape hole on the sheet to meet different need. IIt can be used as sound-absorbing material for building ceilings and wall panels; it can be used for exquisite decorative orifice plates for building stairs, balconies, and environmental protection tables and chairs; it can be used for protective covers for mechanical equipment, gorgeous speaker grills, food, feed, and mines. Grinding sieves, mine sieves, I-shaped sieves, stainless steel fruit blue, food cover, fruit plate and other kitchen utensils for kitchen equipment, as well as shelf nets for shopping malls, decorative exhibition stands, ventilation nets for grain storage, and water seepage filtration for football field lawns. Water filter. Perforated mesh is also widely used in the electronics industry, such as dustproof and soundproof covers for audio systems, etc.

roller sheet punching machine

Loading detail

Hot Searches