In strong wooden case(s), suitable for long-distance ocean/parcel post/air freight or land transportation and to change of

climate, well protected against moisture and shocks.

|

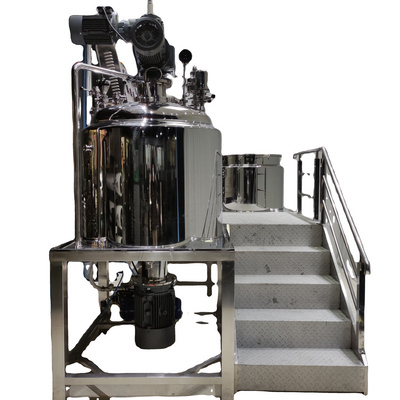

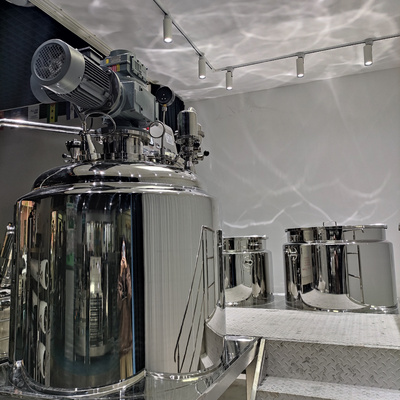

Type

|

|

Fixed type

|

|

|

|||

|

Material

|

|

SUS316L for all contact parts and SUS304 for external

|

|

|

|||

|

Mixing

|

|

Siemens motor + reducer

DELTA inverter(Option: Horizontal motor/ABB motor/Ex-proof motor) |

|

|

|||

|

Bottom homogenizer

|

|

0-3600rpm

|

|

|

|||

|

Discharging way

|

|

bottom discharge/Positive pressure discharge

|

|

|

|||

|

Heating Function

|

|

Electric heating/Steam heating/Single Layer(without heating)

|

|

|

|||