NaN / 0

Fully Automatic Industrial Frozen French Fries Production Line Cassava Fresh Finger Potato Chips Making Machine Price

Get Latest Price

US$ 21000

≥1 Sets

Quick Details

Marketing Type:

Hot Product

Brand Name:

GELGOOG

Place of Origin:

Henan, China

Voltage:

380V

Product Details

Tips:

The potato chips machines

price

and parameters

are for reference only and are configured differently depending on model specifications. Support processing customization. Please consult for details

Product Description

Automatic French Fries Potato Chips Making Machine Project

Automatic potato chip making machine is suitable for midium and large potato chip processing factory business. The equipment operation is simple and convenient, saving labor, 6 workers are enough.

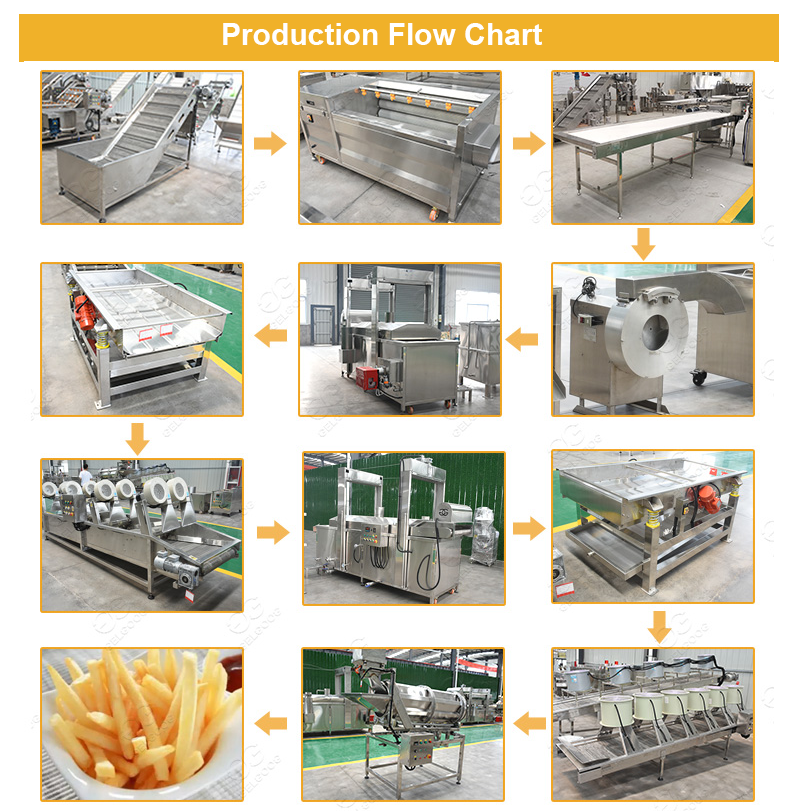

Automatic Potato Chips Making Machine Production Flow

Raw material - elevator - prepare washing - peeling - picking - cutting slice - rising - blanching/scalding - vibration dewatering - cooling deoiling - continuous frying - vibration deoiling - cooling - freezing/flavoring - packing

RELATED PRODUCT

Technical Parameter

|

No.

|

Equipment

|

Power

|

Weight

|

Size

|

||||

|

1

|

Potato Washing Peeling Machine

|

4.37kw/380v/50Hz

|

630 kg

|

3400*900*1400mm

|

||||

|

2

|

Potato Slicing Machine

|

1.1kw/380v/50Hz

|

120kg

|

950*800*950mm

|

||||

|

3

|

Impurity Removal

|

2.2kw/380v/50hz

|

500kg

|

2600*1000*1300mm

|

||||

|

4

|

Rinsing Machine

|

6.6kw/380v/50Hz

|

800kg

|

4000*1200*1300mm

|

||||

|

5

|

Blanching Machine

|

120kw/380v/50Hz

|

1400kg

|

5000*1200*1300mm

|

||||

|

6

|

Vibrating Dewatering Machine

|

0.5kw/380v/50Hz

|

230kg

|

1800*1000*1300mm

|

||||

|

7

|

Electric Frying Machine

|

180kw/380v/50Hz

|

1500kg

|

5000*1100*2200mm

|

||||

|

8

|

Vibrating Deoiling Machine

|

0.5kw/380v/50Hz

|

230kg

|

1800*1000*1300mm

|

||||

|

9

|

Potato Chips Freezer

|

100kw/380/50hz

|

5000kg

|

8500*3300*3000mm

|

||||

|

10

|

Potato Chps Packing Machine

|

6kw/380v/50hz

|

1200kg

|

3000*3000*2600mm

|

||||

|

Note:

Here just list some main machines of whole potato chips production line

|

Total

|

|

|

Length 58m*Width 3m

|

||||

Technical Data for 500kg/h Automatic Potato Chips Making Machine

– Length of the entire production line is about 58 meters.

– Water consumption: 1 cubic meters per hour.

– Workers needed are about 4-6 people.

– Land needed to install potato chips production line is 200 square meters.

– Electric consumption is 300 Kw/h.

– Oil consumption is 25-30 liters per hour (Mixed oil for palm oil).

Cooperative Client

COMPANY PROFILE

CONTACT OUR SERVICE

Hot Searches