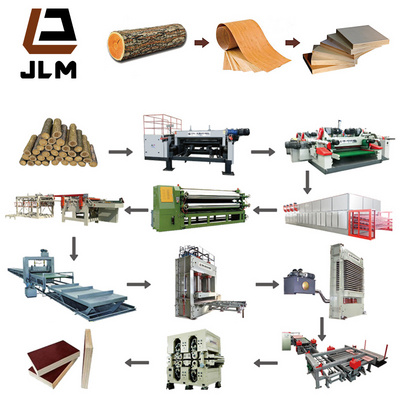

◎Increase the diameter of the roller and increase the working strength ◎Increase the wood supporting mechanism to effectively process bent wood.

◎Strengthen the power,effectively deal with all kinds of hard miscellaneous wood.

◎Enhance the fuselage structure and increase the service life.