NaN / 0

Automatic PCB Etching Machine / PCB Circuit Board making machines

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Place of Origin:

Beijing, China

Brand Name:

SXY

Model Number:

SK700-2

Machine Name:

Automatic PCB Etching Machine / PCB Circuit Board making machines

Product Details

Product Description

Automatic PCB Etching Machine / PCB Circuit Board making machines

This automatic PCB etching machine is suitable for making circuit board,like aluminum PCB, FR-4 board.

The surface of the copper-clad plate is chemically etched to remove the unwanted copper conductor to form a circuit pattern.

|

PCB Etching Machine Advantage:

|

|

|

|

|

||||

|

1.Transparent glass is used in the upper cover and side window of the machine to facilitate the observation of the spraying situation and the conveying of the workpiece.

|

|

|

|

|

||||

|

2.The etching section adopt the horizontal swing spraying system, quick-detachable nozzle, convenient maintenance and repair.

|

|

|

|

|

||||

|

3.The etching solution is filtered by multiple stages, which can effectively prevent the nozzle from blocking.

|

|

|

|

|

||||

|

4. The washing section adopts cascade washing structure, which can greatly reduce the consumption of fresh water.

|

|

|

|

|

||||

|

5. The machine adopts dc speed regulation, digital display, stable operation and simple operation of centralized electric control box.

|

|

|

|

|

||||

|

PCB Etching Machine Details:

|

|

|

|

|||

|

Machine Model

|

|

SK700-2

|

|

|||

|

Machine Power

|

|

380V/50Hz/60Hz

|

|

|||

|

Working width

|

|

700mm

|

|

|||

|

Plate Thickness

|

|

0.05~3.2mm

|

|

|||

|

Transmission Speed

|

|

0~6 M/Min (adjust)

|

|

|||

|

|

|

size: 700mm W x 2000mm L

pump: 4KW motor x 2sets

double etching with oscillation

heater: titanium -- 6KW

cooling : titanium pipe

nozzle: Fan-nozzles

|

|

|||

|

Rinse area

|

|

700x1200mm

double side spraying

|

|

|||

|

|

|

size: 700mm W x 2000mm L

pump: 4KW motor x 2sets

double etching spray sytem

heater: titanium pipe cooling : titanium pipe nozzle: Fan-nozzles |

|

|||

|

Machine Material

|

|

PP plate, resist high temperature

|

|

|||

|

Machine Size

|

|

10500x1600x1750mm

|

|

|||

|

Protection Function

|

|

1. Temperature Control System

2. Pressure Control System 3. Double Filter System 4. Conveyor Control System |

|

|||

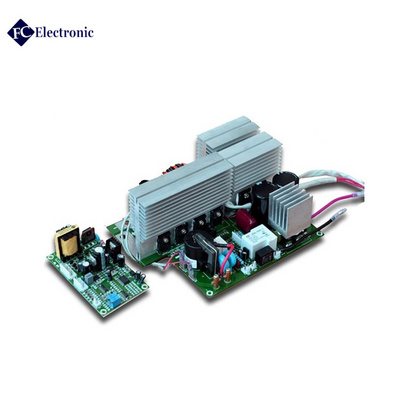

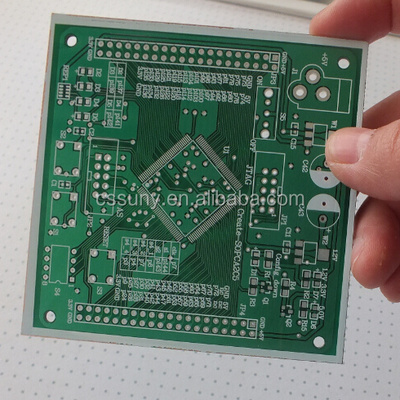

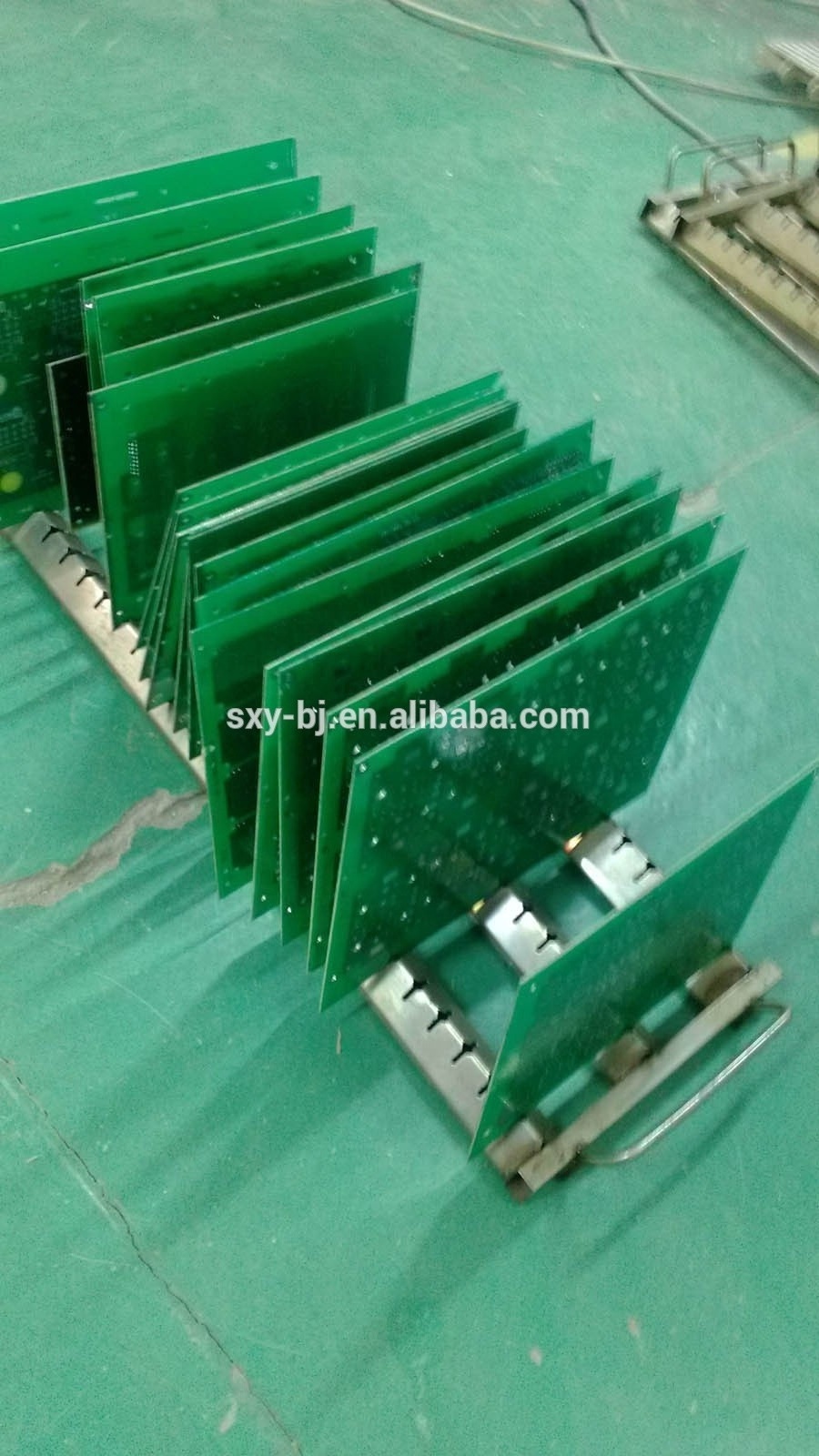

Detailed Images

Related Products

Our Service

Contacts

Hot Searches