NaN / 0

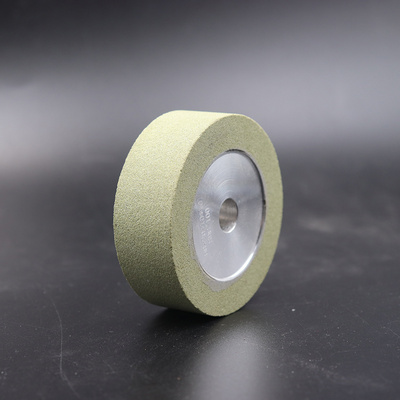

Manufacturer Vitrified Ceramic Bond CBN Diamond Grinding Wheel

Get Latest Price

US$ 8.2

≥1 Pieces

Quick Details

Place of Origin:

Shandong, China

Shape:

Hypotenuse

Abrasive:

Silicon Carbide

Bonding Agent:

Rubber

Product Details

Manufacturer Vitrified Ceramic Bond CBN Diamond Grinding Wheel

Product Description

| Name | diamond block cutting blades | 8202390000diamond block cutting bladesHS code | |

| Bond | Resin bond , Vitrified bond , Metal bond &Electroplated | Material | Aluminium & Steel |

| Abrasive | Diamond and CBN | Packing | purple box, 1pcs /box |

| Size | D:25mm-500mm T: 5mm-40mm H:10mm-127mm | OEM/ODM | Available |

| Type code | 1A1, 1V1, 1EE1, 1FF1, 3A1, 11A2, 6A9, 14A1,14A1R,11V9, 11C9, 4A2, 6A1,6A2, 12A2, 9A3, 1F1,12V2, 1L1, 14EE1, 4B1, 14E1, 4A2P, 11B2, 6A2T, 11V2, 9A1, 1A1R, 1F1, 1A8, 9A1, 9A1B,3K1, 1A1W, 4V2, 1A3, 1A2T,1A2, 12C9 14E6Q, etc. | ||

| Usage | Mainly used for grinding , sharping and polsihing . Widly used in the filed of PCD, CVD, PCBN ceramic, diamond processing, sapphire processing, stone , glass, ceramic, bearing, compressor , car engine processing industry, precision machining,etc | ||

| Sample Cost | Depends on the design, please contact us to discuss further | ||

Grinding is one of the main machining methods in the present semi finishing and finishing, and the grinding wheel is an important tool in the grinding process.

According to different uses, grinding mode and the type of grinding machine, the wheel was made of various shapes and sizes, the common grinding wheel with flat shaped grinding wheel, cylindrical wheel, double bevel wheel, cup wheel, a bowl shaped grinding wheel, disc wheel and so on.

Selection of grinding wheel elements.

(1) hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

(2) when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen, In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

(3) the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

(4) form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of the grinding wheel.

Metal bond CBN tools have become an important tool for hard brittle material grinding because of its high strength, good shape, long lifetime and can meet the request of high speed grinding and ultra precision grinding.

Packaging & Shipping

Special logistics packaging Shock bubble film

Packing Details : Packing, solid bicycle saddle, 50pcs/carton

Delivery Details : 3-30 days after order of Solid bicycle tire tubes

Our Services

Shipping

generally delivery by DHL /UPS/FedEx/TNT, Door to Door expres

High quality

We are in line with Abrasives,Diamond Tools,PDC Materials for more than ten years

OEM

We are a manufacturer that can be customized according to customer needs.

1.LOW MOQ : it can meet your trial order need well ;

2.OEM Accepted: we can do your own brand and design;

3.Good Service: from inquiry to shipment ,we have professional person to deal with the whole processes;

4.Good quality: we have strict quality control system .Good reputation in the market.

5. 24 Hours Technical consultation

In the inquiry, it would be helpful to give the following information:

1. Wheel shape and description.

2. Wheel size.

3. Type of abrasive, Diamond or C.B.N.

4. Grit size.

5. Concentration.

6. Application.

7.Type of bond