NaN / 0

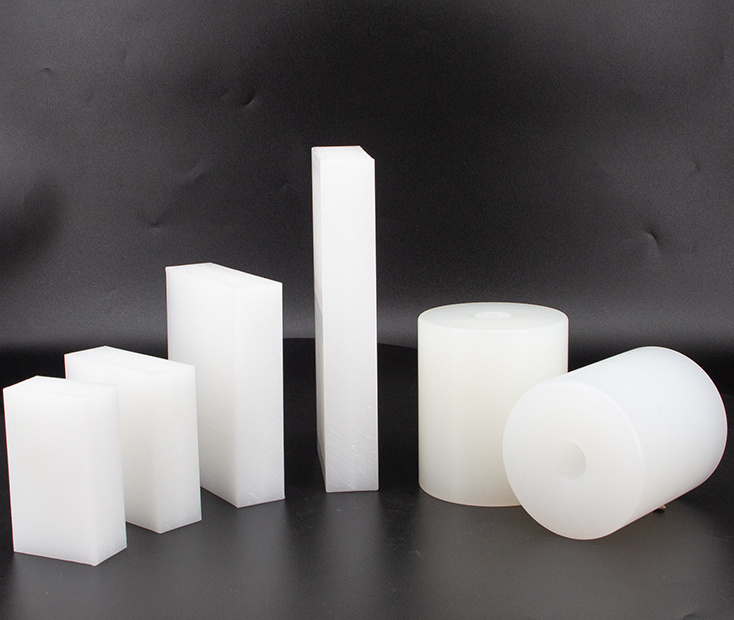

Polypropylene high toughness good chemical resistance PP Polypropylene sheet plate board

Get Latest Price

US$ 0.9

≥500 Pieces

US$ 0.89

≥3000 Pieces

Quick Details

Processing Service:

Cutting, Moulding

Place of Origin:

Guangdong, China

Brand Name:

gz-plastic

Model Number:

s981

Product Details

Products Description

Prouduct Parameters

Polypropylene is a semi-crystalline, thermoplastic engineering material with high toughness and good chemical resistance.Guangzhou Engineering Plastics Industries (Group) Company has studied and applied this material in many industries for many years. With their high temperature resistance, chemical resistance, mechanical toughness,natural lubricity, wear-resistance & insulation properties.

Special properties of PP

1.Long-term thermal stability 110-120 °C

2.Resistant to dilute acids, cleaning agents, numerous solvents

3.Excellent wear resistance under high surface pressure and high sliding speeds

4..High purity, low outgassing in vacuum conditions in accordance

5.Good machinability

5.Good machinability

6.Good chemical resistance to acids, fats and solvents

7.Irradiation resistance

8.Aging resistance

9.Becomes brittle at low temperatures

Regular size

Product color: Black, brown,white, beige, green

Sheet Size: 2000mm X 1000mm X (0.5-100)mm

Rod Size:(5- 150)mm X 1000mm

Product length :100-10000mm

Rod Size:(5- 150)mm X 1000mm

Product length :100-10000mm

|

Item

|

PP Polypropylene sheet

|

|

Material

|

100% new virgin materal, no any recycle material

|

|

Thickness

|

2mm-150mm

|

|

Standard Size

|

1500x3000mm, 1220x2440mm, 1000x2000mm

|

|

Length

|

any size (can be customized)

|

|

Color

|

white, transparent, gray (can be customized )

|

|

Density

|

0.91g.cm

3

|

Product Display

Customized Service

NO.1 Mail samples

Customized samples, our engineers can make exactly the same products according to the samples you provide,measure the specifications and test the product materials.

NO.2 Provide Drawings

We support CAD drawings, PDF files, 3D formats for customization, such as STP, STEP, X-T, etc.Confidential handling of products according to your needs.

NO.3 Provide Photos

If there are only photos and no detailed drawings and samples, you can provide detailed size

We are a company that focuses on the research, manufacture, and sale of engineering and high-performance plastics. At the same time, we offer machined plastic components. If you have any problems or want to get the quoted price of any plastics or machined components, please feel free to contact us. Our engineers will reply to you as soon as possible.

Application

Application: PP(Polypropylene) also offers good thermal and electrical insulation and is also resistant to many acid, alkalis and

organic solvents making it an ideal choice for fabrication jobs in chemical and effluent treatment plants.

1.Chemical apparatus

2.Water treatment plants

3.Seals

4.Food processing industry

5.Insulators 6.Ventilation ducts

7.Pallets

8.Drip pans

Test Creatificate

Factory Tour

The plant covers an area of 10,000 square meters, and the production equipment includes Haas imported from the United States, CNC machining centers, wire cutting, spark machines, punching machines, injection molding machines, CNC engraving and milling

machines, CNC gear hobbing machines, CNC lathes, CNC milling machines, grinding machines and other machinery equipment .

machines, CNC gear hobbing machines, CNC lathes, CNC milling machines, grinding machines and other machinery equipment .

Our company is developing in the mode of quality for survival,brand for development and customer's demand,welcome new and old customers to visit our factory for guidance

Our Exhibition

WELL -KNOWN ENTERPRISE COOPERATION

Cooperation with many well-known companies

Q1. We don't have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40℃, and the highest temperature is 300℃. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine, injection molding machine, extruder, molding machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40℃, and the highest temperature is 300℃. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Hot Searches