NaN / 0

Plate and frame oil filter press, also various sludge dewatering screw equipment for solid and liquid separation

Get Latest Price

US$ 1500

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

TOPER

Voltage:

Customized like 220, 440, 480 and so on.

Power:

2200

Product Details

Plate and frame oil filter press, also various sludge dewatering screw equipment for solid and liquid separation

Overview

Filter presses can be divided into plate and frame type and chamber type. It is one kind of i ntermittent filter equipment. It is used for solid-liquid separation of various suspending liquid. Filter plates are pressed by pressing devices , and then suspen sion is pumped into the filter chamber. Solid particles and liquid is separated through filter cloth. The products are simple in structure but good in separating effects, convenient in use, and widely used in mining, metallurgy, petroleum, chemical, textile, printing and dyeing, paper making, foodstuff, alcohol, inorganic salt, coal washing, dyestuff and sewage treatment industries.

Product introduction

Our company suppli es various types of recessed plate and pla te -frame mechanical filter press, hydraulic filter press, membrane filter press, quick open filter press, full-automatic filter press and filter press spare parts.

1. Filter plate specification include: 320 mm , 450 mm , 630 mm , 800 mm , 870mm, 1000 mm , 1250 mm , 1500 mm and 2000 mm etc.

2. Filtration area up to 2000m2

3. Filter plate materials: cast iron, stainless steel , reinforced polypropylene, glass fiber polypropylene etc.

4. Flow forms: open flow, close flow, washable, non-washable, middle feeding and corner feeding etc.

5. Filter plate pressing modes: manual screw pressing, electric mechanic pressing and hydraulic cylinder pressing , Special filter press can be made on request.

S tructure and operating principle

1. Filter press consists of frame, filter plate, pressing system (manual, mechanical or hydraulic) and electric control cabinet.

2. Frame consists of base, push ing plate, tail plate and beam and frame supports the pressing device and filter plates.

3. Filter plates are installed on the beam between tail plate and push plate, with filter cloth sandwiched in them.

4. In operation, the pressing device (cylinder piston rod or screw) drives the push plate to press the filter plate and filter cloth between push plate and tail plate. Filter chamber are formed between pressed filter plates and materials get into the filter chambers through the feeding inlet of tail plate. Solid particles are remained in filter chambers form ing into cakes, while liquid is discharged out of the machine through press cake and filter cloth. To wash the press cakes, washing water can be introduced through the washing inlet of the tail plate. In similar manner, dry ing the filter cakes with compressed air going into the washing inlet .

5. S tructure of p late - frame type and chamber type filter p ress is the same . E xcept the filtering part that consists of one plate, one frame and filter cloth, with filter chamber between plate and frame.

6. Liquid stream of filter press can be divided into open stream and close stream. Open flow refers to that the filtrate is discharge directly from the outlet of filter plate; Close flow refers to that the filtrate is collected from various filter plate before being discharge d out of the filtrate port.

H ow to order filter press

1. Select the model, plate and frame materials, pressing mode and filtering form by considering the filter press introduction and parameters.

2. According to your products, select open flow or close flow, washable or non-washable, and specify the conditions in the contract.

3. The unit is provided without pump. To order the unit complete pumps, state it in the contract.

4. Our company can supply non-standard model to meet your special demands.

Various of our filter press in details.

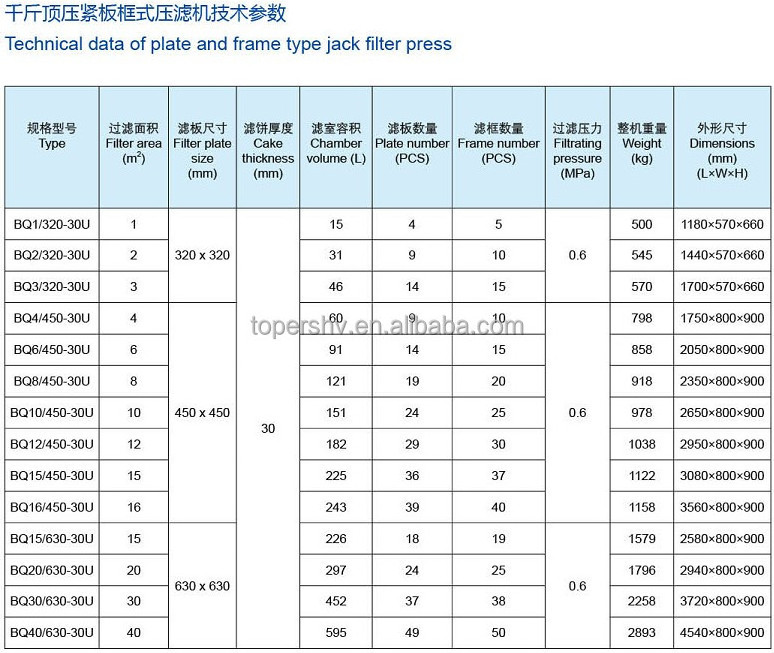

1. Jack Filter Press, use screw jack or hand hydraulic device to reach pressing device.

2. Hydraulic Filter Press, use electric hydraulic unit to reach pressing device.

3. Membrane Filtre Press, with the function of second squeeze, can delivery air or water into the plate to reach second squeeze after the cake forme, then lower cake mositure will get.

4. Automatic Filter Press, usually means the plate opeing by the plate shifting device, usually also we can equip more automatic device to reach higher automatic degree.

5. Cast Iron Filter Press, all material is cast iron, most used for high temperature fitlration mixture handle.

6. Stainless Steel Filter Press, all material is stainless steel, hot used in food, medicine and chemistry industry.

7. Cotton Cake Filter Press, usually used for fermentation, enzymes, gelatin and others high precise requirement industries.

8. Round Plate Filter Press, with higher of filtration pressure about 2.0Mpa hot used for kaolin, ceramic and building materials.

9. Multi layer stainless steel frame filter, all parts of the machine sealed use silicone rubber seals, no leakage and good sealing performance, by use different microns membrane to reach higher filtering accuracy.

About our company-- Zhengzhou Toper Industrial Equipment Co., Ltd.

Zhengzhou Toper is the leading supplier of industrial equipment in China, and also the professional exporter and service provider of filter and separation equipment. Also, we focus on full service for filtering project from design to after-sales service and fast supply of spare parts.

Since 2006, Zhengzhou Toper has supplied products and service to over 200 enterprises of 30 more countries and areas excluding China mainland. Southeast Asia: Indonesia, Malaysia, the Philippines, and Thailand; West Asia: Turkey, Uzbekistan and Tajikistan; Northeast Asia: South Korea, Mongolia; Middle East: Israeli, Palestinian, Oman, Bahrain, Iran; Europe: Russia, Italy, Spain, Ukraine, Finland, Poland, Romania; North America: Canada, America; South America: Mexico, Guatemala, Argentina, Brazil, Chile, Peru, Bolivia; Africa: South Africa, Algeria and so on.

Our filter and separation equipments are widely used in mining, metallurgy, petroleum, chemical, environmental protection, electroplating, food, oil, biological, beverage, brewing, textiles, printing and dyeing, papermaking, inorganic salt, coal washing, sewage treatment, ceramics, leather such industries.

If any need you can contact our person Joycee Chen with below infos.

Hot Searches