NaN / 0

Rotary drill head for drilling rig / Tricone Drill Head /Tricone Drill Bit

Get Latest Price

US$ 800

≥1 Pieces

Quick Details

Place of Origin:

Shandong, China

Brand Name:

OilMan

Product name:

Rotary drill head for drilling rig / Tricone Drill Head

Size:

3 7/8"to 26"

Product Details

Rotary drill head for drilling rig / Tricone Drill Head /Tricone Drill Bit

Product Description

The tricone bit is the most popular drilling bit in the world,it can be widely used for Oil & Gas Drilling, Mining, Water Well, Geological Exploration areas.Our tricone bit divideds into metal sealed drill bit and rubber sealed bit.

1,The bearings adopt high precision radial sliding two way thrust bearings,teeth bearing surface hardfacing of hard alloy layer,the roller bearing is made of alloy after welding to improve the carrying capacity and anti bite ability.

2,Using high-precision metal seal. The metal seal is sealed by a carefully designed metal seal ring as a bearing, and two highly resilient rubber seals are located in the palm and the seal area of the teeth as a static seal. The optimized seal compression ensures that the two metal rings The sealing surface always maintains good contact.

3,Steel ball locking cone, suitable for high speed.

4,The use of a limited pressure differential and to prevent the drilling fluid into the lubrication system of the whole rubber reservoir, to provide a good lubrication guarantee for the bearing system .

5,Using the new grease with high resistance to 250 degrees Celsius and anti-wear.

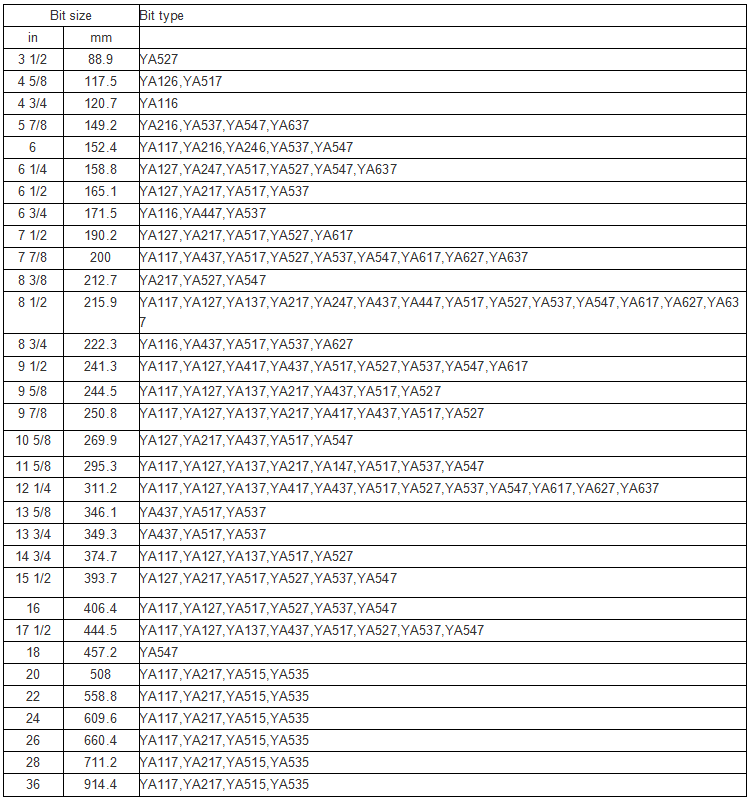

Bit type:

|

Bit size |

Bit type |

|

|

in |

mm |

|

|

7 7/8 |

200 |

IADC437, IADC 447, IADC 517, IADC 537 |

|

8 1/2 |

215.9 |

IADC 417, IADC 437, IADC 447, IADC 517, IADC 527, IADC 537, IADC 547 |

|

8 3/4 |

222.3 |

IADC437, IADC447,IADC517,IADC527 |

|

9 1/2 |

241.3 |

IADC437, IADC447,IADC517,IADC537,IADC547 |

|

9 7/8 |

250.8 |

IADC437,IADC517 |

|

10 1/2 |

266.7 |

IADC517,IADC537,IADC547 |

|

10 5/8 |

269.9 |

IADC517,IADC537,IADC547 |

|

12 |

304.8 |

IADC517,IADC537,IADC547 |

|

12 1/4 |

311.25 |

IADC417,IADC437,IADC447,IADC517,IADC537 |

|

13 1/2 |

342.9 |

IADC517,IADC537,IADC547 |

|

14 3/4 |

374.7 |

IADC517,IADC537,IADC547 |

|

17 1/2 |

444.5 |

IADC517,IADC527 |

|

18 7/8 |

479.4 |

IADC517,IADC537 |

1,The teeth bearing surface hardfacing of hard alloy layer,the roller bearing is made of alloy after welding to improve the carrying capacity and anti bite ability.

2,The 0 - ring sealing ring of the bearing adopts high - saturation nitrile rubber with high wear resistance and high temperature resistance. The sealing ring section is enlarged to reduce the sealing pressure, and the outer end lug is sealed to improve the sealing reliability.

3,Steel tooth bit welding new wear-resistant materials, while maintaining high drilling speed of steel teeth while improving the life of the cutting teeth.

4,The drill bit is made of high strength and high toughness carbide teeth,give full play to the high wear resistance and excellent cutting ability of the tooth cutter with optimized designe of the number of rows of teeth, the number of teeth, the height of the teeth and the unique shape of the alloy teeth.

Bit type:

Products Show

Advantage

Advantage

The Advantages of Using a Tri Cone Over Other Drill Bits

1. High temperature heat treatment forged alloy steel .

2. Carbide teeth with high strength and toughness work more efficiently

3. Tooth palm lip hard welding surface with hard alloy, effectively prevent the drill bit wear and tear work

4. Head OD protection to effectively reduce head wear in abrasive formation and extend bit work

5.Directional jet enlarges lateral flow area and helpful bottom hole cleaning and increase of ROP

6. Lubricating system protection of bearing and seal system of bit extend bit work life

7. API REG Connection

8.Rubber sealed and metal sealed bearing

Related Products

Packaging & Shipping

Packing : Wooden case, or customized packing.

Delivery time : Stock or depending on quantity

Delivery: By express, truck, train, air, sea