NaN / 0

PVC PP PE Single Double Wall Corrugated Pipe Hose Electrical Conduit Drain Water Supply Extrusion Making Machine

Get Latest Price

US$ 15000

≥1 Pieces

US$ 14000

≥2 Pieces

Quick Details

Screw Design:

Double-screw

Screw L/D Ratio:

38:1

Screw Speed (rpm):

39 rpm

Place of Origin:

Shandong, China

Product Details

Product Description

PVC PP PE Single Double Wall Corrugated Pipe Hose Electrical Conduit Drain Water Supply Extrusion Making Machine

|

NO.

|

Specification

|

Quantity

|

|

1

|

Single-screw extruder with automatic loading device

|

1set

|

|

2

|

Mould

|

1set

|

|

3

|

Corrugated forming machine

|

1set

|

|

4

|

Haul-off machine

|

1set

|

|

5

|

Chipless cutting machine

|

1set

|

|

6

|

Two stations winding machine

|

1set

|

|

7

|

Perforator (optional)

|

1set

|

|

8

|

Laminating machine (optional)

|

1set

|

Details Images

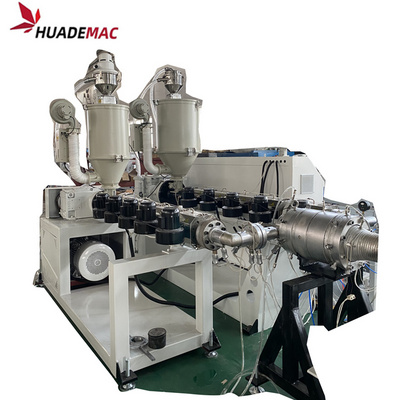

1.

Single-screw extruder with automatic loading device

:

According to the requirements of different diameters and different output of pipes, we have many models of special single screw extruders to choose from. It adopts a specially designed screw structure, which can evenly heat, plasticize the raw material and extrude pipes .

(1) Motor brand: Siemens

(2) Inverter brand: ABB or Delta

(3) Contactor brand: Siemens

(4) Relay brand: Omron

(5) Breaker brand: Schneider

(6) Material of screw and barrel: 38CrMoAlA.

(7) Heating method: Ceramic heating

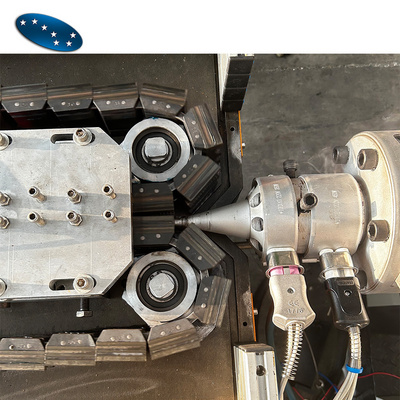

2. Mould:

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good.

(1) Material: 40Cr and nitrided.

(2) Size: Customized

3.

Corrugated forming machine

:

The corrugated formig device can calibrate and cool the pipe from the mould.

(1)

Structure Horizontal.

(2)

Guide track material is 40Cr.

(3) Block seat material is 40Cr, nitrided.

(3) Block seat material is 40Cr, nitrided.

(4)

AC motor: 2.2KW x 1 set.

(5)

Blocks is cooled by air cooling fan.

4.Haul-off machine

The haul-off machine can transport pipe.

(1)

Hauling track type: Belt.

5.

Chipless cutting machine

:

The special cutting machine adopts rotary clamping device, is suitable for different pipe diameters, avoids the trouble of frequently changing clamping device.

(1)

Cutting scope: Customized

(2) Control means: Pneumatic control

6.Two stations w

inding machine

:

It u

ses the delicate and exact meter counting and code setting unit made in Korea

.

(1) T

wo stations automatic winding unit without stopping.

(2)

Torque Motor:4-6N/M or customizable.

|

Machine Model

|

Pipe Diameter

(mm)

|

Production Speed (m/min)

|

Production Capacity

(kg/h)

|

Total Power

(kw/h)

|

|

SJ30/33

|

6~10

|

10~12

|

20

|

12

|

|

SJ45/33

|

10~32

|

6~8

|

40

|

20

|

|

SJ65/33

|

25~50

|

6~8

|

70

|

30

|

|

SJ75/33

|

50~160

|

3~6

|

150

|

70

|

Final products

You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.

2

. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)

3. Delivery.

4. We will provide after-sales service:

(1) Field installation

and

commissioning;

(2) Field training your workers;

(3) Field maintenance and repair service ;

(4) Free Spare Parts ;

(5) Video/Online technical support.

Reviews by customers

Certifications

Cooperation Brands

FAQ

1.Are you manufacturer or trading company?

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.Warranty: 1 year.

We are manufacturer.

2.Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

3.Delivery time: 20~30 days.

4.Payment terms:

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

5.Warranty: 1 year.

Contact Us

Hot Searches