●

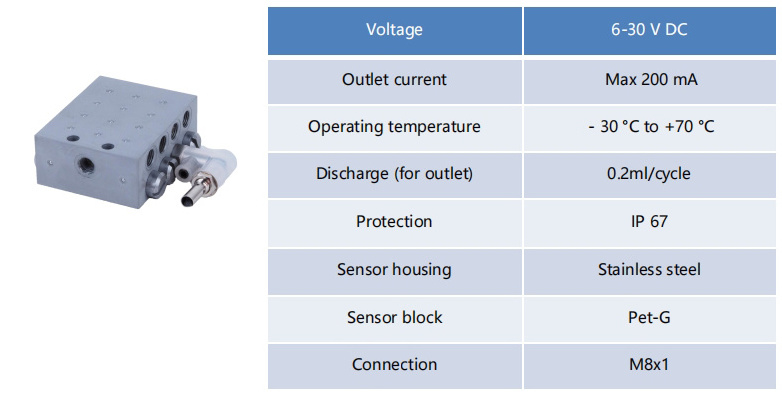

Min. Pressure: 20 Bar, 300 psi

●

Max. Pressure: 350 Bar, 5075 psi

●

Operating Temperature: -40 ~ +200 ºC

●

Lubricant viscosity:

Oil- NLGI 2

●

Material:

nickel-plated steel

●

Proximity Type: PNP or NPN 10- 30V DC - 200 mA