NaN / 0

House structure light gauge steel keel channel making roll forming machine prices

Get Latest Price

US$ 11000

≥1 Sets

US$ 10000

≥3 Sets

Quick Details

Type:

Tile Forming Machine

Tile Type:

Colored Glaze Steel

Production Capacity:

30-35m/min

Place of Origin:

China

Product Details

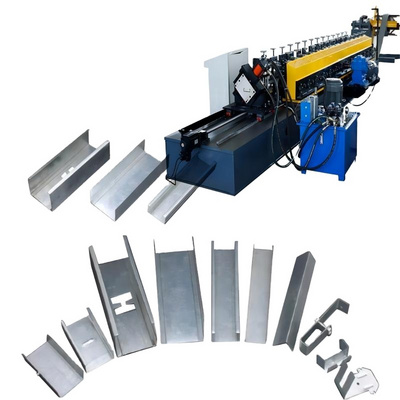

House structure light gauge steel keel channel making roll forming machine prices

House structure light gauge steel keel channel making roll forming machine prices

Product Description

|

Material |

Colored steel sheet, galvanized steel sheet, aluminum sheet |

|

Thickness of coil sheet |

1.0-2.0mm |

|

Efficiency width |

25/30mm |

|

Machine details |

|

|

Roller material |

High grade NO. 45 forged steel with 0.05mm hard chrome plating |

|

Shaft material |

High grade NO. 45 carbon wrought steel |

|

Cutting blade |

Cr12 mould steel with quenched treatment |

|

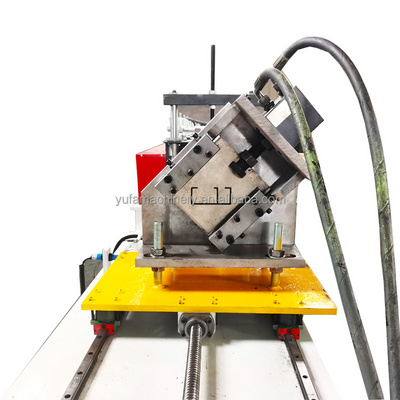

Diameter of shaft |

70mm or as your requirement |

|

Main frame |

300 H steel |

|

Forming steps |

16 stations |

|

Productivity |

30-35m/min |

|

Hydraulic station power |

5.5 KW |

|

Hydraulic pressure |

10-12MPa |

|

Appearance size |

7700mm*1500mm*1500mm |

|

Hydraulic oil |

40# hydraulic oil |

|

Electric tension |

380V 50 Hz 3 Phase or as your requirement |

|

Cut Mode |

Hydraulic forming after cutting off |

|

Cutter materia |

Cr12 Heat Treatment |

|

Electronic control system |

PLC, Touch Screen, Encoding counter |

|

Color |

Blue, green or yellow or as your requirement |

|

Rolling material |

45# steel,roller surfaces polishing, hard plating |

Main Features

1.This roll forming machine can rollform metal roofing sheet. After roll formed by this roll forming machine, the surface will be very smooth and beautiful without any scratch on surface.

2.Rollforming process:uncoiler, rollforming, forming step effect, cut to length.

——————

working flow

——————

3.Fully Automatic Control System with PLC.

4.Easy operation: Key in the length and quantity on the control panel.

5.two years warranty for free, and beyond two years if any part broken, tell us and pay us we delievery any part u need. And support technical skills for machine for whole life.

6.we also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

7.One roll forming machine only can produce one profile. and we also can produce double or three layer roll forming machine.

Related Products

Hot Searches