NaN / 0

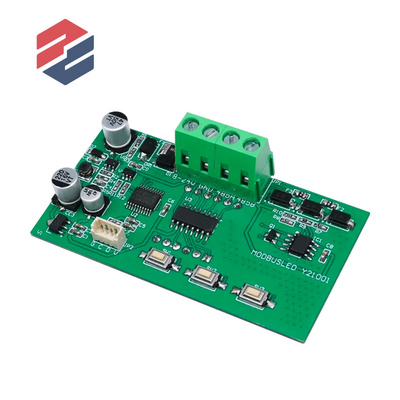

Smt Aluminum Based Led Lighting Circuit Pcb Smd Led Pcb Assembly Mcpcb Metal Pcb

Get Latest Price

US$ 3

≥1 Pieces

US$ 2.5

≥100 Pieces

US$ 2

≥1000 Pieces

US$ 1

≥3000 Pieces

Quick Details

Number of Layers:

1-40 ( ≥30 layers needs review )

Base Material:

Aluminum base,

Board Thickness:

0.2-7.0mm(≤0.2mm needs review)

Board Size:

200*300mm

Product Details

Products Description

|

Seq

|

Item

|

capability

|

|

1

|

Base Material

|

FR-4, High TG FR-4 , Halogen Free material ,CEM-3,CEM-1,PTFE,Rogers ,Arlon ,Taconic,Aluminum base,PI ,etc

|

|

2

|

Layers

|

1-40 ( ≥30 layers needs review )

|

|

3

|

Finished inner/outer copper thickness

|

0.5-6OZ

|

|

4

|

Finished board thickness

|

0.2-7.0mm(≤0.2mm needs review),≤0.4mm for HASL

|

|

|

|

Board thickness≤1.0mm: +/-0.1mm

1Board thickness>2.0mm: +/-8% |

|

5

|

Max panel size

|

≤2sidesPCB: 600*1500mm

Multilayer PCB: 500*1200mm |

|

6

|

Min conductor line width/spacing

|

Inner layers: ≥3/3mil

Outer layers: ≥3.5/3.5mil |

|

7

|

Min hole size

|

Mechanical hole: 0.15mm

Laser hole: 0.1mm |

|

|

|

Drilling precision: first drilling First drilling: 1mil

Second drilling: 4mil |

|

8

|

Warpage

|

Board thickness≤0.79mm: β≤1.0%

0.80≤Board thickness≤2.4mm: β≤0.7% Board thickness≥2.5mm: β≤0.5% |

|

9

|

Controlled Impedance

|

+/- 5 % Ω(<50Ω),+/-10%(≥50Ω),≥50Ω+/-5% (needs review)

|

|

10

|

Aspect Ratio

|

15:01

|

|

11

|

Min welding ring

|

4mil

|

|

12

|

Min solder bridge

|

≥0.08mm

|

|

13

|

Plugging vias capability

|

0.2-0.8mm

|

|

14

|

Hole tolerance

|

PTH: +/-3mil

NPTH: +/-2mil |

|

15

|

Outline profile

|

Rout/ V-cut/ Bridge/ Stamp hole

|

|

16

|

Solder color

|

Green,yellow,black,blue,red,white,matte green

|

|

17

|

Component mark color

|

white,yellow,black

|

|

18

|

Surface treatment

|

OSP: 0.2-0.5um

HASL: 2-40um Lead free HASL: 2-40um ENIG: Au 1-10U’’ ENEPIG: PB 2-5U’’/ Au 1-8U’’ Immersion Tin:0.8-1.5um Immersion silver: 0.1-1.2um Peelable blue Carbon ink Gold plating: Au 1-150U’’ |

|

19

|

E-Test

|

Flying probe tester : 0.4-6.0mm,max 19.6*23.5inch

|

|

|

|

Min spacing from test pad to board edge : 0.5 mm

|

|

|

|

Min conductive resistance : 5 Ω

|

|

|

|

Max insulation resistance : 250 MΩ

|

|

|

|

Max test voltage : 500 V

|

|

|

|

Min test pad diameter : 6 mil

|

|

|

|

Min test pad to pad spacing : 10 mil

|

|

|

|

Max test current : 200 MA

|

|

20

|

AOI

|

Orbotech SK-75 AOI : 0.05-6.0mm,max 23.5*23.5inch

|

|

|

|

Orbotech Ves machine : 0.05-6.0mm,max 23.5*23.5inch

|