NaN / 0

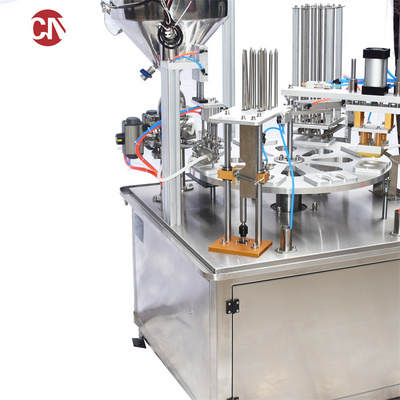

milk yogurt juice water k cup filling machine coffee cup filling sealing machine

Get Latest Price

US$ 1700

≥1 Sets

US$ 1500

≥200 Sets

US$ 1300

≥500 Sets

US$ 1100

≥1000 Sets

Quick Details

Machinery Capacity:

400BPH, 1000BPH, 100BPH, 200BPH

Packaging Material:

Plastic, Paper, Metal, Glass, Wood

Filling Material:

Beer, Milk, Water, Oil, Juice

Filling Accuracy:

High Precision Filling Level

Product Details

Liquid aseptic small PET bottle filling machine for milk juice/beverage Filling Capping Machine

The GFK-160 Numerical Control Quantitative Wine, Drink, Liquid Filling Machine uses micro-computer to control the mini-pump on

filling time and the rotation rate of electric motor so that the machine can fill the liquid fluently at high accuracy.

The machine is compact and portable. The body uses stainless steel so it is durable and easy to clean. The machine has a

self-prime pump that can suck in the liquid from your container and then output by the nozzle. It can be used to fill many

different types of clear thin liquid,including water, olive oil, fuel, drinks, vinegar, milk etc.

Stainless steel body

The machine body adopting the ss material, it is hard and no rust.

Filling Head

The filling head use one-way nozzle, drip proof and not flow back.

Filter

The filter can filtrate the impurity inside the liquid to make sure the pump and hose won't block.

Foot Pedal

There is two working methods:Manual mode: to press to foot pedal

Auto mode: in auto mode to adjust the waiting time

Auto mode: in auto mode to adjust the waiting time

Control panel

The panel shows clearly and can control and adjust the function very easy.

Filling Pump

The pump Max flow 3.5L per minute.The filling volume 3-3500ml adjustable.

Chun Nobel has high-precision CNC machining tools and machining centers, advanced production equipment, fine technique and strict and perfect quality management system, and moreover, we gather professional elites and science and technology team with leading level, so as to make full use of new technologies, new techniques and new materials to guarantee stability and reliability of products.Our product quality originates from advanced manufacturing means, and the concept of fine products stems from continuous innovation.

Chun Nobel

has a large number of professionaltechnical talents and technical service teams to research and develop and make innovation of

the production of beers, drinks and foods

. From the engineering designand equipment manufacture to equipment installation ofthe projects of users, by following the operation concept of "making scientific and technological innovation and pursuing excellence" and the service mission of "creating values for customers whole heartedly, the company provides pre-treatment equipment and technical service of

the whole line to users in beer, drinks. water, iced tea.cooking oil and medicine and chemical sector.

|

Complete Set of System

|

|

|

|

|||

|

Plate Type UHT system

|

Plate Type Juice Pasteurized system

|

Batch Powder dissolution system

|

In-situ cleaning system

|

|||

|

Tubular UHT system

|

Tubular Type Juice Pasteurized system

|

High Speed Powder dissolution system

|

Milk online standard system

|

|||

|

High Fructose System

|

Milk Pasteurizing System

|

Aseptic tank system

|

Degassing system

|

|||

|

Scraped surface heat exchange system

|

Continuous sugar melting system

|

Sugar content control system

|

Multi intelligent on-board mixing system

|

|||

|

Spare Parts

|

|

|

|

|||

|

Plate heat exchanger

|

Tubular heat exchanger

|

Valve

|

Pump

|

|||

|

Seal ring

|

Storage tank

|

Pipe fittings

|

Sanitary-grade flexible pipe

|

|||

|

Agent Brand:

|

|

|

||

|

SELI

|

Conductivity measurement

|

Temperature measurement

|

||

|

Pressure measurement

|

Fill level measurement

|

Wilo pumps

|

||

Products Description

CIP system

Automatic program control ensures the excellent cleaning effect.Automatic adding of acid and alkali. Concentration is automaticallycontrolled by using concentration monitor,which reduces thedemand for manpower and ensures personal safety.Select proper spray ball in accordance with the capacity of the

container.Optimized CIP cleaning function could reduce the number of CIPcleaning times.Reserved connector could facilitate the connection withotherequipments.

Our control software obtained patent right.

Plate Type Pastuerizer

The CN FX Plate Juice Pasteurizer features automatic control ofpasteurization temperature, automatic flow diversionandcontinuous recording for full traceability together with high heatrecovery for low operating cost.Available in capacities rangingfrom 6.000 to 35.000 /h, the Plate Juice Pasteurizer is pre-assembled and factory-testedwith water to ensure fastinstallation and commissioning for reliable performance and highROl over a long service life.

Milk Pre-processing production line

1,

Purified water part

2,

Production Line Machine

a,

High speed emulsifier

b,

Sanitary Pump

c,

Filter

d,

Protein mixer

e,

Sanitary Pump

f,

Filter

g,

Preparation tank

h,

Sanitary Pump

i,

Filter

j,

Homogenizer

k,

Tubular type UHT Milk Sterilizer Machine

l,

Aluminum foil three in-one filling

machine

machine

l,

Capping machine

3,

Steam part

4,

Cooling water system

Filling Machine

Filling Machine for different package:

Bottle, Can, gable top carton ,etc

Feel free talk us your drinks Package. So we arrange the machine as your request

Marketing Campaign

Chun Nobel concentrates on designing.manufacturing and installing production processing system in

food and drinks industry

, including plate-type ultra-high temperature system, continuous sugar melting system, milk pasteurization system, degassing system,aseptic tank system,in-situ ceaning system,etc. Chun Nobel holding the spirit of doing works professional, we can provide whole line of production equipments , pre-treatment equipment and technical service of the whole line to users in

Milk,Yogurt,

Liquor,

beer,

Carbonated drinks,

vegetable and fruit Juice,

drinks, water, iced tea,cooking oil and medicine and chemical sector.

We has a large number of professional technical talents and technical service teams to research and develop and make innovation of the production of

beers, drinks and foods.

From the engineering design and equipment manufacture to equipment installation of the projects of users, by following the operation concept of "making scientific and technological innovation and pursuing excellence"

Certifications

Exhibition

Installation Instructions

Team on-site installation service

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Our Advantages

Our cooperated clietns:

We have take part in exhibition in worldwide. and cooperated with famous brand such as the company as below mention

Shipment

FAQ

Q1: Are you a trading company or a manufacturer?

A1:

We are a professional manufacturer. Our factory occupy 20,000㎡ in Jiangsu

Province. We have large-sized standard production workshop and advanced equipment. Welcome to visit us at any time.Q2: I want to start the business from 0 to 1, how can you help me?

A2: We provide the one-stop solution for complete liquid food processing line. Our service include:

Province. We have large-sized standard production workshop and advanced equipment. Welcome to visit us at any time.Q2: I want to start the business from 0 to 1, how can you help me?

A2: We provide the one-stop solution for complete liquid food processing line. Our service include:

①Technical consultation,

②Proposal design,

②Proposal design,

③Processing flow design,

④Factory layout design,

⑤Equipment manufacturing,

⑥Field installation, commissioning &training,

⑦Package design & purchasing,

⑧Ingredients purchasing,

⑨Life-long after sales sevice, etc.

Q3: How can we visit your

company?

company?

A3

: If you come from abroad, we can pick you up at Shanghai Airport. We can also show you our factory by online video

visiting.

visiting.

Q4: What payment methods your company accept?

A4:

We accept most of the payment methods, mainly T/T, L/C irrevocable at

sight .

sight .

Q5: I haven't done business with you company before, how can I trust your company ?

A5:

Our company committed to fruit processing since 2007, have 15 years experience and 100+ successful projects in worldwide. At the same time, we have got CE and

ISO9001 certificates, Alibaba onsite inspection certificate. And you can also choose the third inspection facility to visit us.

Q6: What' s delivery time of your company?

ISO9001 certificates, Alibaba onsite inspection certificate. And you can also choose the third inspection facility to visit us.

Q6: What' s delivery time of your company?

A6:

The delivery time depend on the quantity of your order. Usually 30 days formachinery, 90 days for complete processing line.

Hot Searches