NaN / 0

Refractory Gunning Mixes for BF, BOF, EAF, Tundish

Get Latest Price

US$ 170

≥5 Tons

Quick Details

SiO2 Content (%):

3-15%

Al2O3 Content (%):

75%-85%

MgO Content (%):

0

CaO Content (%):

Lillte

Product Details

Refractory Gunning Mixes for BF, BOF, EAF, Tundish

Product Description

Performance

Low cement catable is developed on the basis of clay and refractory castables by Kerui Group. It mainly includes low cement, super low cement, no cement or ultra micro powder+sol, etc. Many advantages of refractory castables gather to it, such as high density, low apparent porosity, high strength, low abrasion, thermal shock resistance, corrosion resistance, etc.

Character

The prominent character of low cement castable is high and strong densification which brings benefits of its using:

The CaO in it is lower, which reduces the produce of eutectic phase in material and develop its refractoriness, high temperature strength and slag erosion resistance.

The water used for the blending of castable during construction is only 1/3~1/2 of water for normal use, which realizes low apparent porosity and high bulk & density.

After moulding by casting, the cement compound produced during maintenance is less. There is no damage of large amount of hydrated bond during heating and roasting, which will reduce the medium temperature strength. But for low cement castable, the strength is increasing with the increase of heating temperature.

Adjusting the size composition of castable can compound self-flow castable and pump irrigation castable.

Application

Low cement castable is used in the back kilneye, wicket cover and back of cooling machine of cement rotary kiln and other thermal equipment with good performance and long service life.

Technical Index

Physical and Chemical Indexes of High Alumina low cement castable:

|

Low Cement Castable |

Corundum |

High Alumina |

Clay |

||||

|

KR-90 |

KR-80 |

KR-70 |

KR-60 |

KR-50 |

KR-40 |

||

|

Chemical composition % ≥ |

Al 2 O 3 |

90 |

80 |

70 |

60 |

50 |

40 |

|

CaO |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

|

|

Bulk density g/cm3≥ |

110℃×24h |

2.95 |

2.75 |

2.6 |

2.5 |

2.4 |

2.3 |

|

1500℃×3h |

2.9 |

2.7 |

2.6 |

2.4 |

2.4 |

2.3 |

|

|

Compressive strength MPa ≥ |

110℃×24h |

60 |

45 |

45 |

40 |

40 |

40 |

|

1500℃×3h |

80 |

75 |

70 |

60 |

60 |

60 |

|

|

Breaking strength MPa ≥

|

110℃×24h |

8 |

7 |

6 |

6 |

6 |

6 |

|

1500℃×3h |

10 |

10 |

10 |

8 |

8 |

8 |

|

|

Linear Change PLC % ≤

|

110℃×24h |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

|

1500℃×3h |

-0.5 |

-0.5 |

-0.5 |

-0.5 |

-0.5 |

-0.2 |

|

|

Max. service temperature ℃ |

1700 |

1600 |

1500 |

1450 |

1400 |

1350 |

|

Related technical parameters should be appointed temporarily in the contract according to the specific service environment.

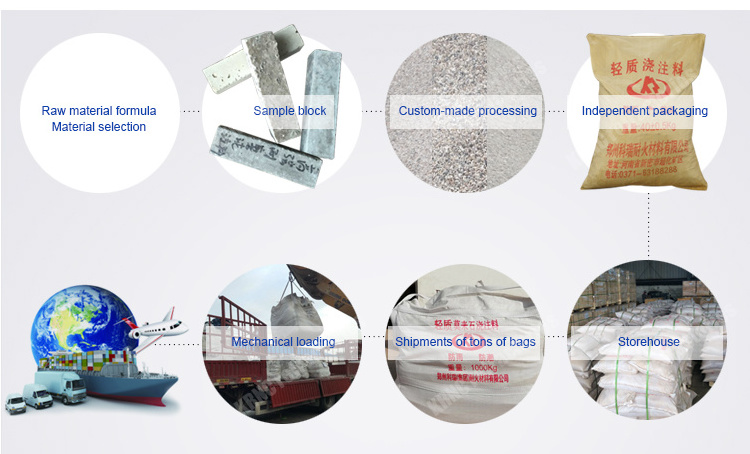

Making Process

Packing & Shipment

Case show

Hot Searches