NaN / 0

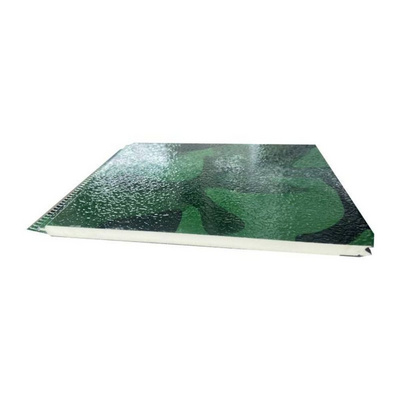

Lightweight Fireproof Outdoor Sandwich Wall Panels Price For Interior Or Exterior House Building

Get Latest Price

US$ 15.78

≥300 Square meters

US$ 9.98

≥30000 Square meters

Quick Details

Project Solution Capability:

total solution for projects

Application:

Office Building

Design Style:

Modern

Place of Origin:

Fujian, China

Product Details

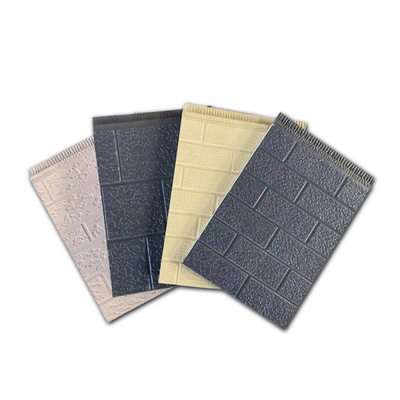

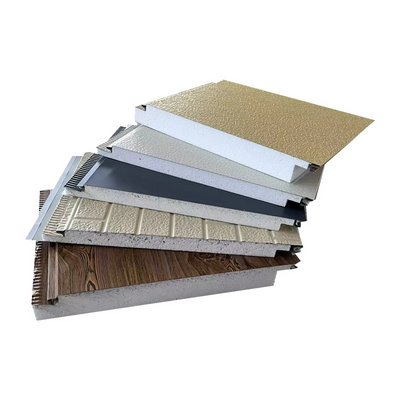

Prefabricated Exterior Wall Fibre Cement Sandwich Panels

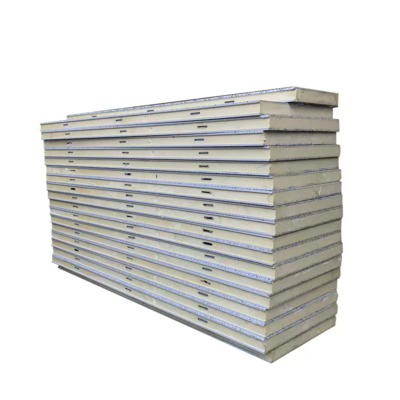

Sandwich panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

Feature

1. Easy and quick to install;

2. Excellent load and span capabilities;

3. Significant savings in site installation costs;

4. Energy saving thermal insulation;

5. Superior air tightness for controlled environments;

6.Good reactions to fire properties;

8. Durable, long lasting, stood the test of time in the extremes of harsh climate.

Specification:

|

ZJT Sandwich Wall Panel |

||||

| Material | Wall Thickness(mm) |

Surface Density(kg/m2) |

Weight Total(kg/m2) | |

| Material | Plaster | |||

|

Cellular Lightweight Concrete Blocks |

180 | 328 | 80 | 408 |

| 120 | 207 | 80 | 287 | |

| 90 | 173 | 80 | 253 | |

| Hollow Concrete Blocks | 180 | 175 | 80 | 255 |

| 120 | 115 | 80 | 195 | |

| 90 | 90 | 80 | 170 | |

| Vanjoin Panel | 100 | 78 | 0 | 78 |

| 75 | 53 | 0 | 53 | |

| 60 | 39 | 0 | 45 | |

Sandwich panel is currently a common building material products, has two layers of metal panels and middle polymer insulated core repression.

Forming an outer steel full account of the structure and strength requirements, taking into account the appearance, the inner surface layer is formed into a flat to suit a variety of needs. Filling system used is closed cell molecular structure, can prevent moisture condensation.

Two layers of metal sheets, middle polymer insulated core repression like EPS, rock wool, glass wool.

Application

Widely used in steel structure workshop, simple movable house roof, wall, air clean ceiling and partition, prefab house, commercial and residential buildings, etc

Packaging & Shipping

1). Free packing, normal pallet + packing belt

2). Standard exporting packing, good pallet+pearl wool+corner protective paper+packing belt+plastic thin film

3). Loading: Normally 18 pallets per 20' container or according to clients' requirements

Explore More Products

Hot Searches