NaN / 0

Mbr Wastewater Treatment Plant Domestic Sewage Treatment Plant waste water clarifier

Get Latest Price

US$ 20000

≥1 Sets

Quick Details

Place of Origin:

Guangdong, China

Brand Name:

Hongjun

Material:

standard, stainless steel or carbon steel

Weight:

standard

Product Details

Mbr Wastewater Treatment Plant Domestic Sewage Treatment Plant waste water clarifier

Product Description

Design Principles

-

We harshly design based on the relevant state environmental protection laws and regulations, standards, to ensure that the effluent could reach the national and local emission standards.

-

Under the premise of design requirements, we use the most advanced, reliable, safe, energy-saving, sanitary , low cost techniques to achieve convenient operation, management, and a stable quality of effluent.

-

During design the water treatment, we also consider and try best to control the discharge of secondary waste pollutions that probably cause from water treatment process, such as concentrate waste, waste gas, to protect environmental sanitation .

-

We consider in all directions to design general layout of whole water treatment plant to be reasonable, compact, and less footprint required.

General Operating Process:

Process Description

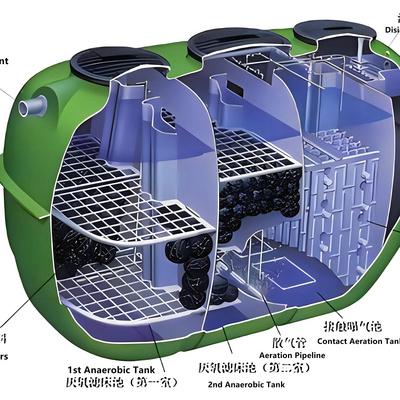

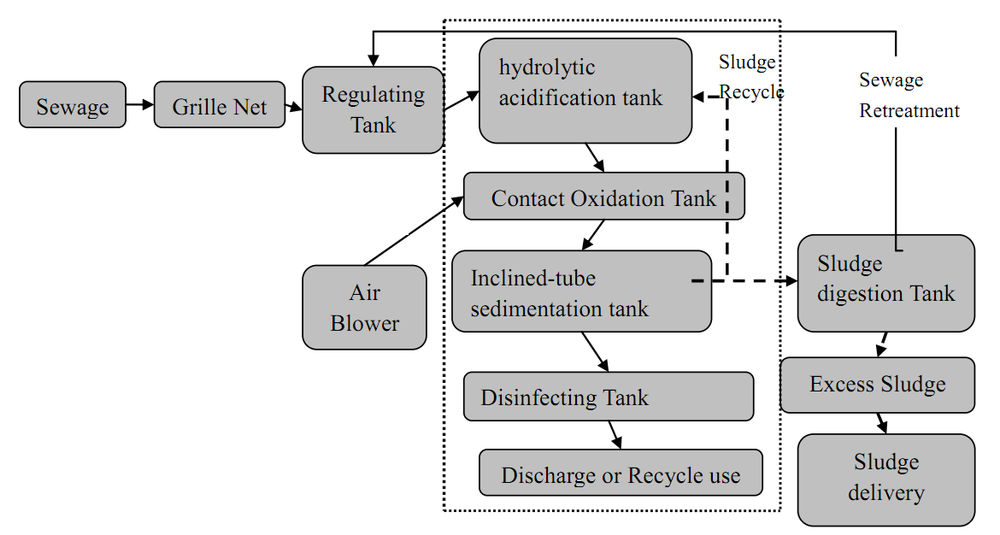

Sewage liquid water passes through a screen in grit chamber to remove all objects like large

suspended maters, hair, dross etc. before they damage sequent equipment. These objects and

floating material are removed and remaining water after achieving uniform flow rate in regulating

tank is pumped into the anaerobic tank here beginning biochemical treatment.

In the anaerobic tank water is undergoing hydrolytic acidification treatment for biological degradation

of organic materials. As partly reduces COD and BOD hydrolytic acidification increases biodegradability

of the sewage water liquid. Then outlet water go into the contact oxidation tank where, it is treated sequently by one stage and two stage contact oxidation in order to substantially degrade the biological content of the sewage which are derived from human waste, food waste, soaps and detergent.

Part of sludge and suspended materials produced in contact oxidation tank are precipitated out by

inclined tube sedimentation . Effluent is coming out from sedimentation tank and is disinfected in

effluent tank before discharge.

Sludge in sludge digestion tank is returned to anaerobic tank and pumped out regularly with truck.

Packaging & Shipping

FCL: Tight ribbon fixing in container for large equipment like vessels or tanks or pipes; carbon packing or original packing for elements like pumps and membrane elements.

LCL: Carbon packing or thin film or gunny bag depends on the types of products.

Our Services

v Project design:

v We can design any project of the water treatment to meet the demands of our clients, considering both the quality of the raw water and the desired standard of the treated water.

v Supply overseas commissioning:

v System will be pre-testing before delivery. Operation will be provided as well. If technicans still require at installation site, all costs involved, including visa fee, air ticket, accommodation costs, etc, are paid by buyer. In addition, each technician should be paid salary every day.

Hot Searches