NaN / 0

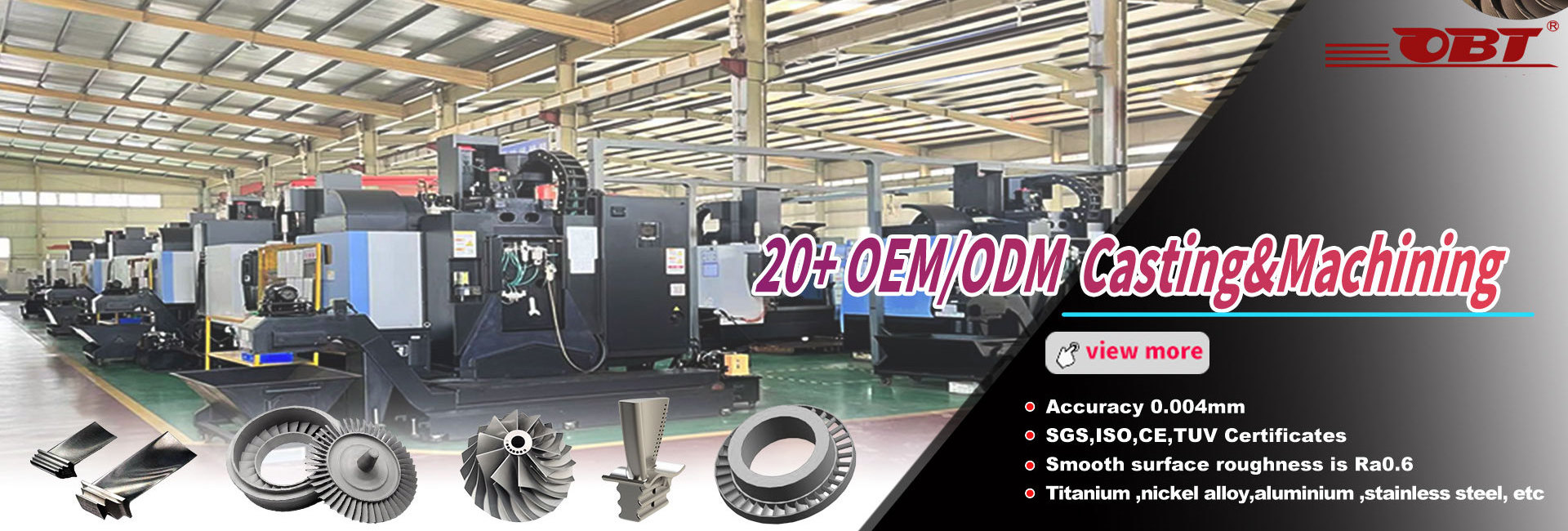

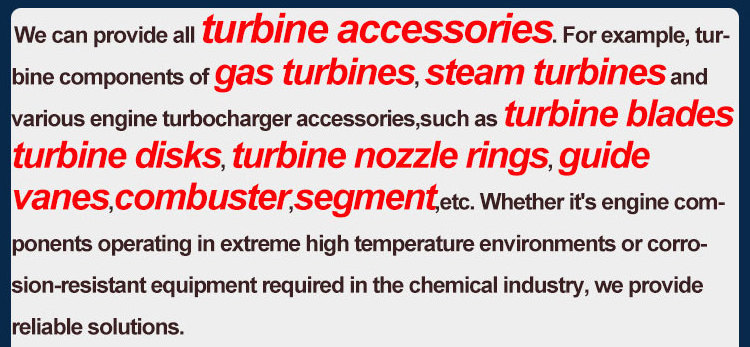

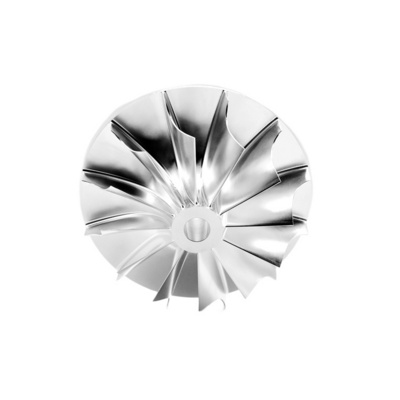

Inconel 713 718 Super Alloy Titanium Metal Alloy Forging Investment Vacuum Casting Gas Engine Axial Turbine Wheel

Get Latest Price

US$ 59.8

≥1 Pieces

US$ 42.3

≥10 Pieces

US$ 22.6

≥100 Pieces

US$ 6.9

≥1000 Pieces

Quick Details

Weight (KG):

1

Place of Origin:

Shandong, China

Brand Name:

OEM/ODM

Engine Model:

Csutom

Product Details

Product Details

|

Product Name

|

Inconel 713 718 Super Alloy Titanium Metal Alloy Forging Investment Vacuum Casting Gas Engine Axial Turbine Wheel

|

|

Tolerance

|

CNC Machining ±0.004mm/Casting ±0.1mm

|

|

Place of Origin

|

Qingdao, Shandong, China

|

|

Processing Craft

|

Sand Casting/Lost Wax Casting/Investment Casting/Vacuum Casting/Forging/CNC Machining/etc

|

|

Surface Treatment

|

A variety of surface treatments and coatings can be produced and customized according to your requirements.

|

|

Type

|

OEM; Customized

|

|

Certification

|

ISO9001:2015 Certified, UL Certification,GE,SGS,TUV,etc

|

|

Packing

|

Carton/Wooden box

|

|

Inspection

|

1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance.

|

|

|

2.Third Party inspection available upon requirement.

|

|

|

3.Optional X-ray detection

|

|

|

4.Fluorescence detection

|

|

Service

|

Drawing Custom

|

|

Mainly Testing Facility

|

Spectrometer,CMM, Tensile testing machine, Impact tester,Hardness tester,X-Ray,Salt spray test box, Pneumatic detection,UV

accelerated weathering tester,dynamic balancing, high-temperature tensile testing,fluorescence test,room temperature mechanical property testing and other testing. |

|

Quality Guarantee

|

2 Years

|

|

Features & Advantage

|

1.High machining accuracy, the flatness within 0.001mm

|

|

|

2.High finish appearance, smooth surface roughness is Ra0.6 after machining.

|

|

|

3.The machining precision is high and the assembly structure is seamless.

|

|

|

4.Smooth appearance, corrosion resistance.

|

|

|

5.Pass Salt Spray Test with 144 Hours.

|

|

Standard

|

ISO , DIN, AISI, ASTM, BS, JIS, etc.

|

|

|

GB/T 14992 GJB 5512.1 HB 7763 HB/Z 140

|

|

Payment

|

L/C,D/A,D/P,T/T,Western Union,Money Gram

|

Surface Coating Technology

|

Name

|

Inner Cavity Cooling Channel Coating

|

External Surface Coating

|

|

Nickel Aluminum Diffusion Coating

|

MTK-NAI

|

MTK-WAI

|

|

Aluminum Silicon Diffusion Coating

|

MTK-NAISi

|

MTK-JAISi

|

|

Chrome Aluminum Diffusion Coating

|

MTK-NAICr

|

MTK-WAICr

|

|

Diamond Aluminum Diffusion Coating

|

MTK-NAICo

|

MTK-WAICo

|

|

Platinum Aluminum Diffusion Coating

|

|

MTK-WPtAl

|

|

Aluminum Diffusion Coating

|

MTK-NAITi

|

MTK-WAITi

|

|

Q Salt Electroplating Platinum

|

|

MTK-WPt

|

|

Compressor Inorganic Phosphate Coating

|

|

MTK-WAI

|

|

MCrAIY Coating Technology

|

|

MTK-RZ

|

|

TBC

|

|

MTK-TBC

|

|

CVD Vapor Phase Aluminizing

|

|

|

|

Chromated Aluminum Coating Technology

|

|

|

Main materials:

Hot Searches