NaN / 0

Aluminum Foil Jumbo Roll Price 8011 aluminum foil material kitchen aluminum foil use for food

Get Latest Price

US$ 2400

≥3 Tons

US$ 2350

≥5 Tons

US$ 2300

≥10 Tons

US$ 2200

≥30 Tons

Quick Details

Use:

kitchen aluminum foil use for food

Type:

Roll

Thickness:

14 micron

Alloy:

1235 8011

Product Details

Product Description

Aluminum Foil Jumbo Roll Price 8011 aluminum foil material kitchen aluminum foil use for food

Aluminium foil (or aluminum foil in North America; often informally called tin foil ) is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm (7.9 mils); thinner gauges down to 6 micrometres (0.24 mils) are also commonly used. [1] In the United States, foils are commonly measured in thousandths of an inch or mils . Standard household foil is typically 0.016 mm (0.63 mils) thick, and heavy duty household foil is typically 0.024 mm (0.94 mils). The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated with other materials such as plastics or paper to make them stronger and more useful.

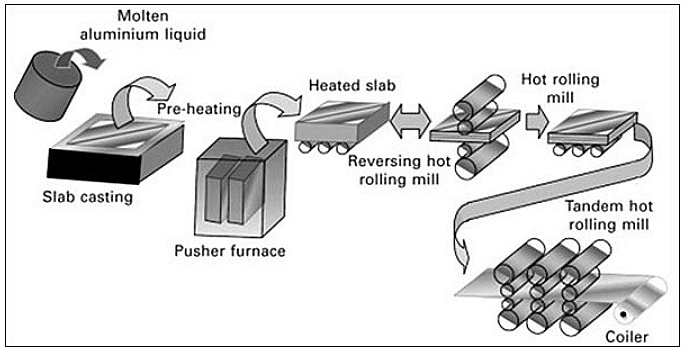

Aluminum foil is produced by rolling aluminum slabs cast from molten aluminum in a rolling mill to the desired thickness. To maintain a constant thickness, a technician monitors the rolling mill sensors to ensure the pressure on the slab is correct. Sensors are able to tell the technician if the pressure is too great or not enough and then the technician can adjust the rollers to apply more or less pressure. It is then coiled and sent to the cold rolling mill. To avoid breakage because of the thinness, the foil is doubled in the cold rolling mill and the rolled to the desired thickness. Aluminum foil provides a complete barrier to light, oxygen, moisture and bacteria. For this reason, foil is used extensively in food and pharmaceutical packaging. It is also used to make aseptic packaging that enables storage of perishable goods without refrigeration.

| 1000 Series (Called commercial pure aluminum, Al>99.0%) | |

| Alloy | 1050, 1060, 1070, 1100 |

| Temper | H111, H112, H12/H22/H32, H14/H24/H34, H16/H26/H36, H18/H28/H38, H114/H194, etc. |

| Specification | Thickness: 0.3mm-10mm, standard: 0.5mm, 0.6mm, 0.8mm, 1.0mm, 2.0mm, etc. |

| Width: 600-1220 | |

| Color: Ecru, Black, Blue, Gold, Silver, Red, Rose-gold, custom | |

| Application | Industry |

| Feature | High aluminum content, good antirust perfomance, corrosion preventive, etc. |

| 3000 Series (Called Al-Mg-Mn Alloy) | |

| Alloy | 3003 3004 3005 3102 3105 3A21 |

| Temper | H111, H112, H12/H22/H32, H14/H24/H34, H16/H26/H36, H18/H28/H38, H114/H194, etc. |

| Specification | Thickness: 0.3mm-2mm |

| Width: 600-1220 | |

| Color: Ecru, Black, Blue, Gold, Silver, Red, Rose-gold, custom | |

| Application | Domestic appliance, vehicle bottom, humid environment, etc. |

| Feature | High antirust performance, good corrosion resistance, well welding property, good plasticity, etc. |

| 5000 Series (Called Al-Mg Alloy) | |

| Alloy | 5005 5052 5083 5182 |

| Temper | H111, H112, H12/H22/H32, H14/H24/H34, H16/H26/H36, H18/H28/H38, H114/H194, etc. |

| Specification | Thickness: 0.3mm-2mm |

| Width: 600-1220 | |

| Color: Ecru, Black, Blue, Gold, Silver, Red, Rose-gold, custom | |

| Application | Aviation alumminum material, industry, etc. |

| Feature | Low density, light in weight, high tensile strength, high extensibility, etc. |

| 6000 Series (Called Al-Mg-Si Alloy) | |

| Alloy | 6061 6063 6082 |

| Temper | H111, H112, H12/H22/H32, H14/H24/H34, H16/H26/H36, H18/H28/H38, H114/H194, etc. |

| Specification | Thickness: 0.3mm-2mm |

| Width: 600-1220 | |

| Color: Ecru, Black, Blue, Gold, Silver, Red, Rose-gold, custom | |

| Application | Aircraft parts, camera parts, coupler, ship fittings, metals, electronic accessories and connectors, decoration, etc. |

| Feature | Excellent interface, characteristics, easy coating, high strength, good serviceability, good corrosion resisant performance, etc. |

Detailed Images

Application

The first pre-formed, all-foil food packaging containers appeared on the market in 1948. This grew into the complete line of die-formed and air-formed foil containers now sold in every supermarket. A spectacular period of growth occurred in the 1950s and 1960s. TV dinners, packed in compartmental trays, began to reshape the food products market. Packaging foil is now divided into three major categories: household/institutional foil, semi-rigid foil containers and flexible packaging. For decades, the use of foil has grown steadily in each of these categories.

- Food Preparation : Aluminum foil is “dual-ovenable” and can be used in both convection and fan-assisted ovens. A popular use of foil is to cover thinner sections of poultry and meat to prevent overcooking. The USDA also provides recommendations on limited uses of aluminum foil in microwave ovens.

- Insulation : Aluminum foil is 88 percent reflective and is widely used for thermal insulation, heat exchanges and cable liners. Foil-backed building insulation not only reflects heat, aluminum sheet also provides a protective vapor barrier.

- Electronics: Foil in electrical capacitors provides compact storage for electric charges. If the foil surface is treated, the oxide coating works as an insulator. Aluminum foil capacitors are commonly found in electrical equipment, including television sets and computers.

- Geochemical Sampling : Aluminum foil is used by geochemists to protect rock samples. Foil provides a seal from organic solvents and does not taint the samples as they are transported from the field to the lab.

- Art and Decoration : Anodizing aluminum foil creates an oxide layer on the aluminum surface that can accept colored dyes or metallic salts. Through this technique, aluminum is used to create inexpensive, brightly colored foils.

Related Products

Packaging & Shipping

Explore More Products

Hot Searches