Welcome to our company!

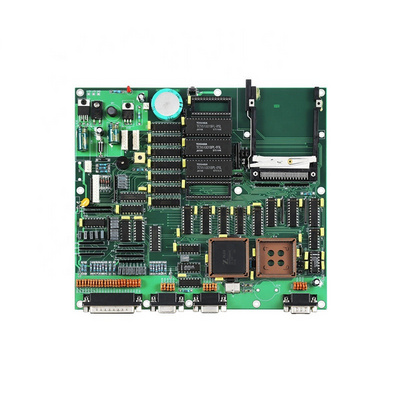

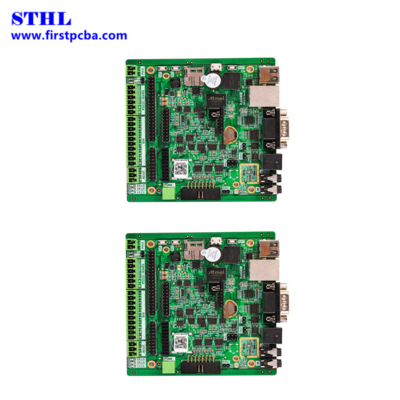

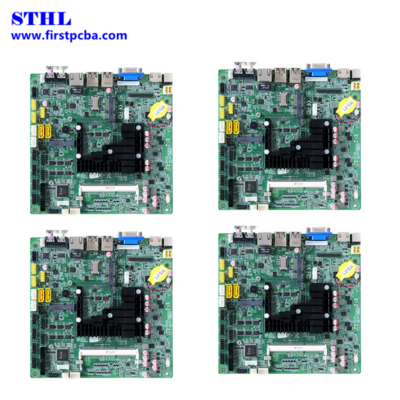

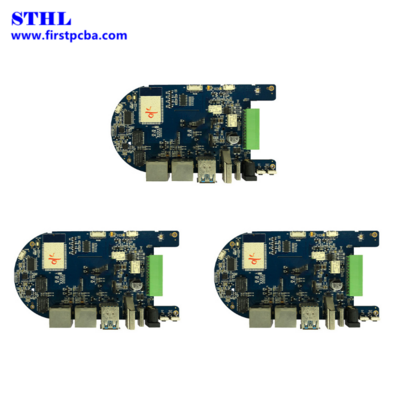

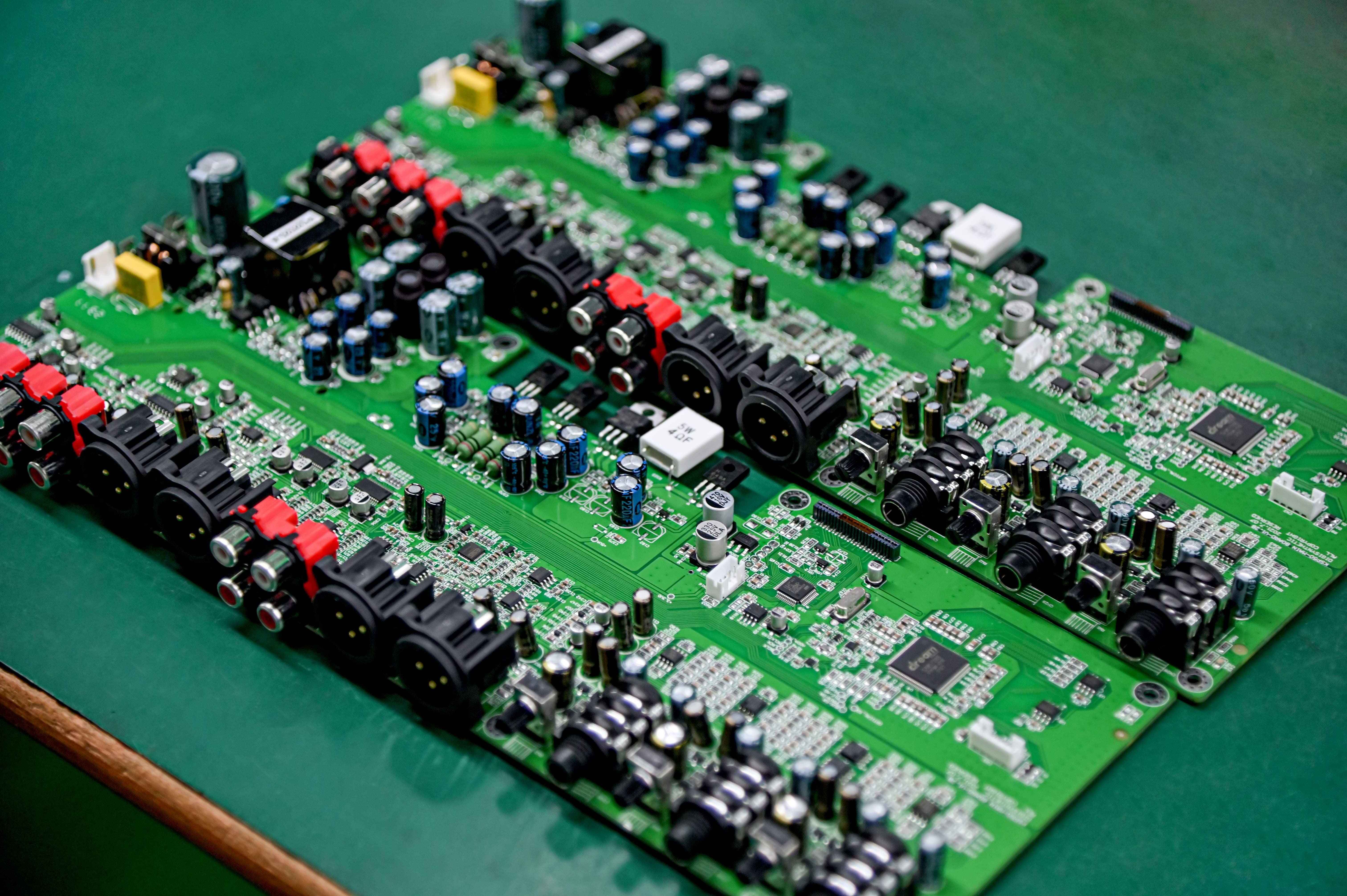

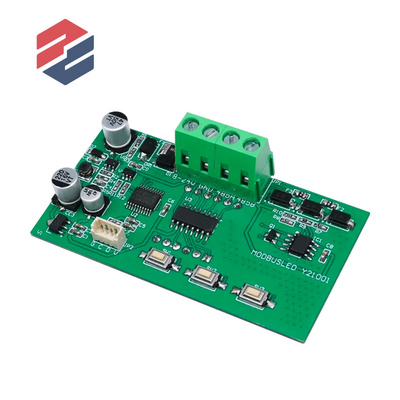

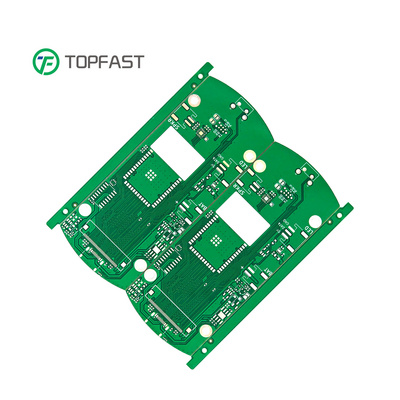

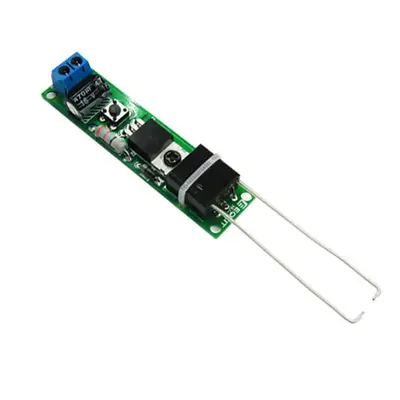

We are a PCBA (Printed Circuit Board Assembly) manufacturer that is dedicated to provide high quality and cost-effective solutions for our customers. We have been in the industry for more than 17 years and have built a strong reputation for providing superior printed circuit board assemblies and services.

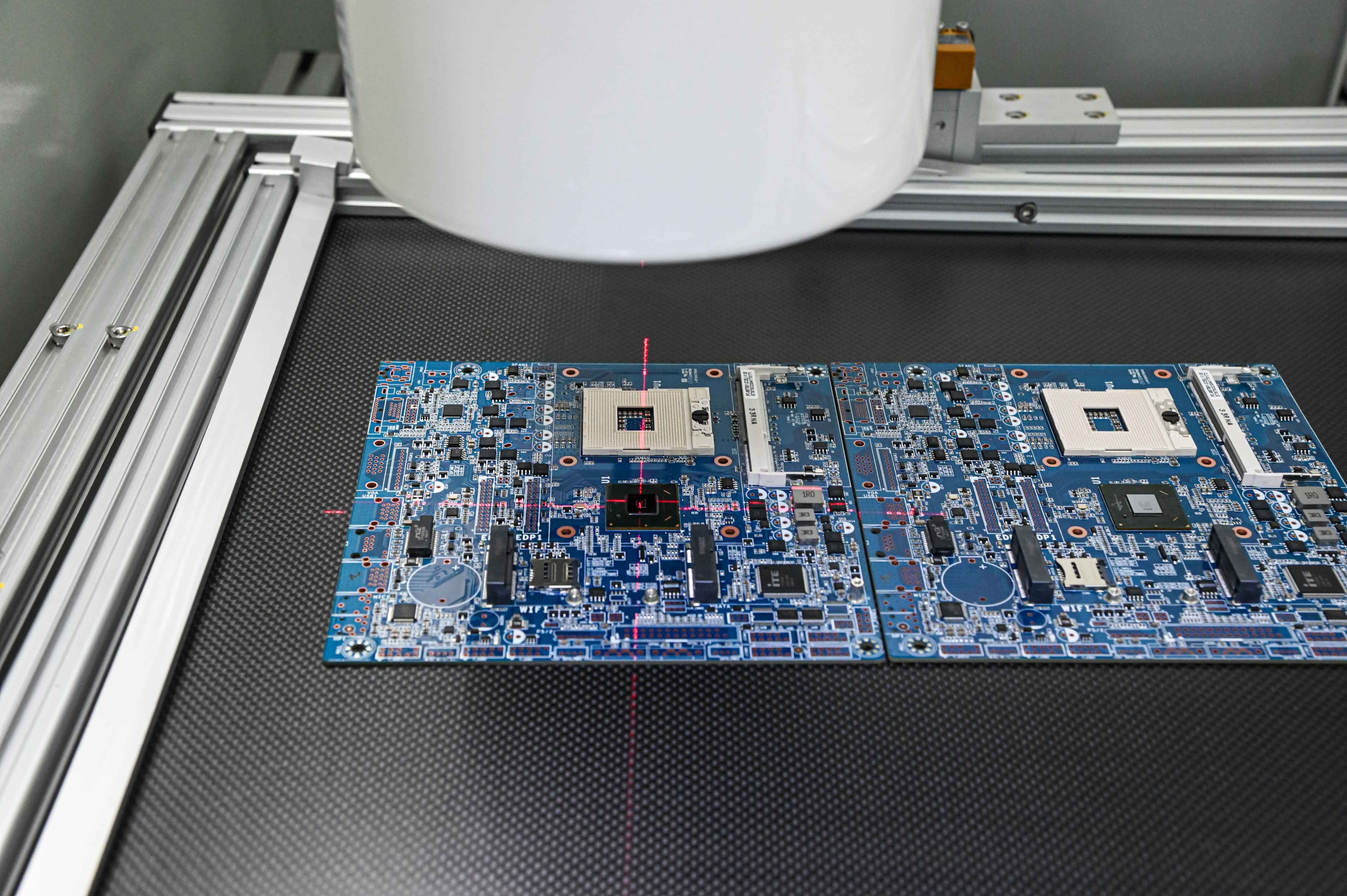

Our team of experienced engineers and technicians are committed to the highest standards of quality and service. We utilize the latest technologies and equipment to ensure that all of our products meet our customers’ requirements. We also have a rigorous inspection and testing process to ensure that our products exceed industry standards.

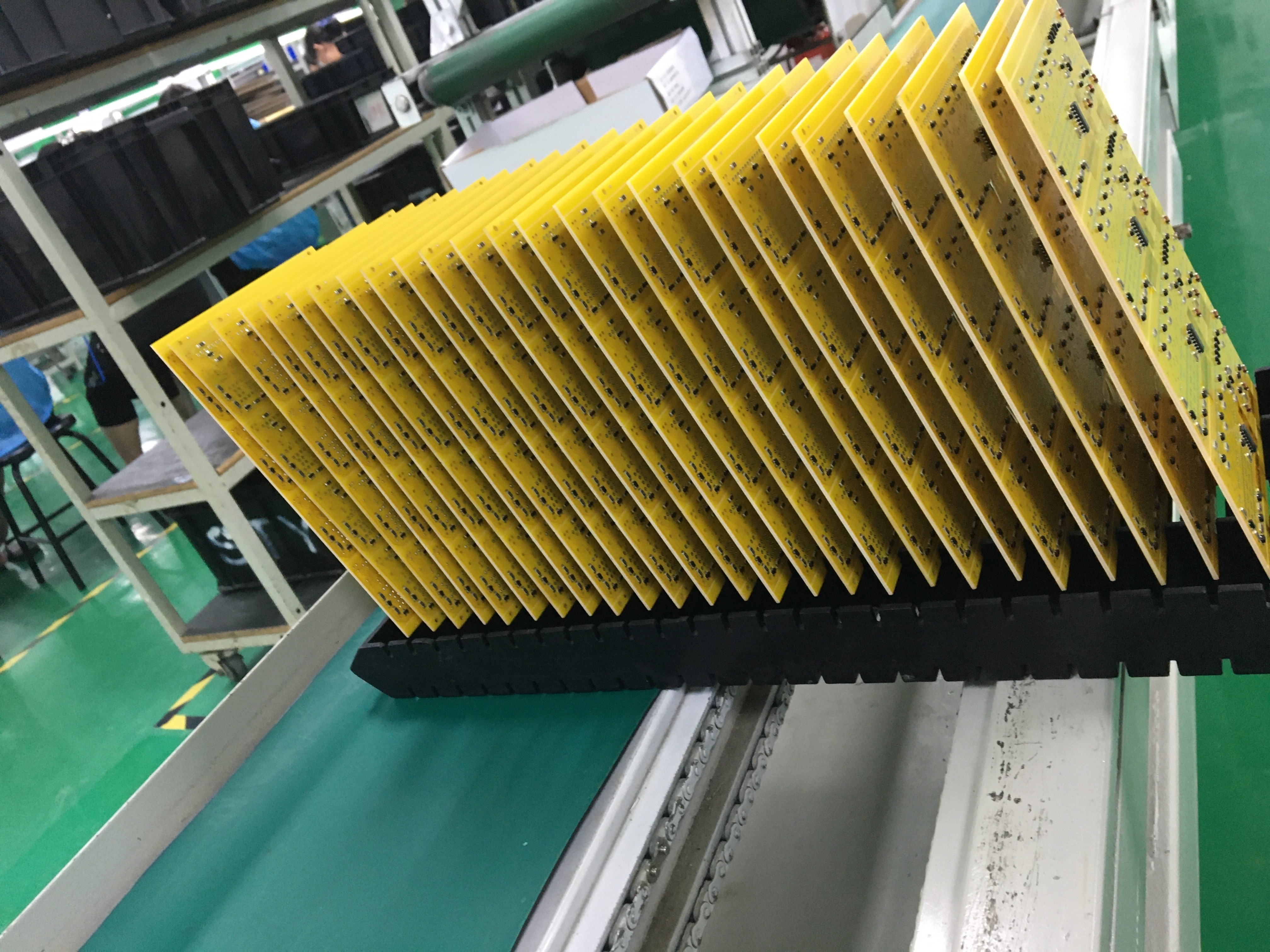

We provide a wide range of services and solutions for our customers, including complete turnkey assembly, partial assembly, box build, rework and repair and more. We also offer design and engineering services to ensure that your product meets your exact specifications.

In addition to our PCBA services, we also provide a wide range of additional services including component sourcing, material management, and warehousing and logistics services. We strive to provide our customers with the best possible solutions to meet their needs.

At our company, we are committed to providing our customers with the highest level of service and quality. We value our customers and take great pride in providing exceptional customer service. We are dedicated to building long-term relationships with our customers and strive to exceed their expectations.

We are confident that we can provide you with the best solutions to meet your needs and exceed your expectations. We look forward to working with you and providing you with the highest level of service and quality. Thank you for considering our company for your PCBA needs.