NaN / 0

automatic paper roll cutting machine for foam/paper/Sticker with laminating function

Get Latest Price

US$ 2000

≥1 Sets

Quick Details

Type:

Paper Cutting Machine

Production Capacity:

30-120pcs/min

Max. workable width:

customized

Place of Origin:

China

Product Details

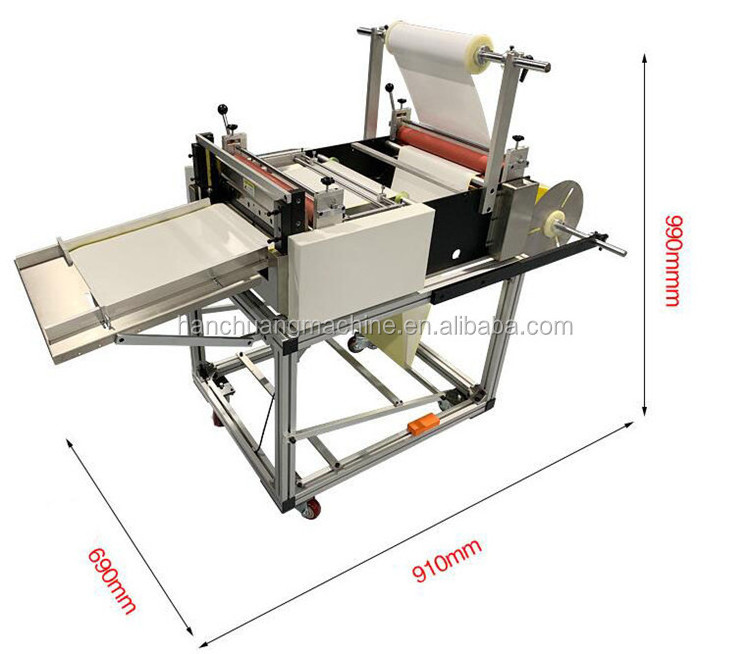

automatic paper roll cutting machine for foam/paper/Sticker with laminating function +8618737189043

Introduction of laminating and cutting machine machine

1. Using microcomputer control, the length, speed and quantity can be adjusted arbitrarily.

2. The overall structure design is reasonable and durable.

3. The operation is simple, instead of manual labor, one machine can hold 3 to 5 people.

4. It has a wide range of applications, and all kinds of roll materials can be cut. 5. The use of inlaid front steel blades has higher hardness, more wear resistance and long service life.

6. Additional brackets are used for double-roll material bonding, which is stable, convenient and integrated, and can be placed on various roll materials for cutting.

7. Install multiple guide devices to realize simultaneous cutting of multiple materials, doubling the efficiency.

Parameters of paper business card slitting machine

|

Model |

300C |

400C |

500C |

600C |

800C |

1000C |

1200C |

1300C |

1500C |

|

Cutting width(mm) |

300 |

100 |

500 |

600 |

800 |

1000 |

1200 |

1300 |

1500 |

|

Voltage |

220V/50/60hz Or customized |

||||||||

|

Cutting length |

0.1-9999.9mm |

||||||||

|

Cutting speed |

30-120pcs/min |

||||||||

|

Cutting Accuracy |

0.1mm |

||||||||

|

Blade material |

sharp steel |

||||||||

|

Optional equipped |

Electric eye Film function Heat sealing and cold cutting Punch function Art blade Round knife Spring system Slotted rubber roller

|

||||||||

Details of film cutting machine

Application of laminating cutting machine

Suitable for cutting all kinds of self-adhesive, release paper, roll paper, kraft paper, insulating paper, fast paper, wrapping paper, heat transfer paper, warning paper, glitter paper, PET/PVC/PE/OPP/BOPP /TOoCA film, release film, protective film, plastic film, electrostatic film, heat shrinkable film, hot melt adhesive film, thermoplastic film, heat transfer film, reflective film, electrostatic film, non-woven fabric, melt blown cloth, planting Flannel, non-woven fabric, knitted fabric, dust-free cloth, conductive aluminum foil, copper foil tape, stainless steel sheet, metal iron sheet, copper tape, tin foil, plastic film, Velcro, elastic band, webbing, cloth strip, pu leather, double-sided tape , EVA foam, sponge and other adhesive tube materials.

paper cutting machine pictures show

Packaging & Shipping

Packaging & Shipping

1. Testing Machine before package

2. Package : Inside plastic bag, outside wooden case.

3. Shipping: By sea, By air.

By sea: if customer not urgently the machine, we advice by sea, even though by sea took time is long, but by sea reduce much money about the freight, and it is good for customer if the machine is heavy and big size.

By air: it is faster than by sea, but its freight is higher much than by sea, so this kind of type always suggest for light, small size and urgently demand machine.

Our Services

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

Hot Searches