NaN / 0

raffia twine rope making machine agricultural straw baler twine machine

Get Latest Price

US$ 380000

≥1 Sets

Quick Details

Screw Design:

Single-screw

Screw L/D Ratio:

33/1

Screw diameter (mm):

60708090 mm

Screw Speed (rpm):

80 rpm

Product Details

PP,HDPE virgin baler twine,packing line ,plastic rope whole line production can contact fantasy 008613153856283

Production Introduction

The machine can produce different size of PP,HDPE virgin or recycled split-film,flat film,cable filler which is widely used in binding twine,baler twine,packing twine, plastic rope.The machine has the characteristics of long life span,easy operation, easy maintenance.The products have high strength which can up to 5.5g/d.

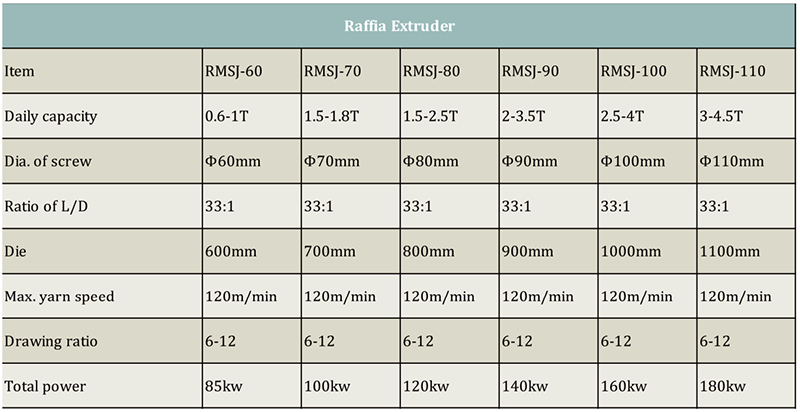

Production Items and Models

Production Features

PLC man-machine interaction interface:realizing intelligent operation of touch screen; realizing the functions of monitoring the operation status and parameters setting in mobile APP.

extruder screw and barrel are made of 38CRMoALA alloy steel, with the hardness above HV950 after nitrification.

the gear reducer adopts 20CrMnTi alloy steel and helical gear material.Extruder spiral barrel adopts aluminum alloy casting heater, durable

Siemens is the main motor. Customers can also choose other international brands

the speed regulation method adopts frequency conversion speed regulation

the reducer is the first brand in China and its quality is guaranteed

equipped with automatic feeding, mixer and dryer

The transmission mode adopts gear transmission, which is durable, has high torque and high transmission accuracy

equipped with metering pump, even out the film

use the automatic screen filter, you can also choose other filters

the water tank is made of stainless steel to prevent rust.Traction roller surface stainless steel material, customers can choose all stainless steel.

The portal frame prevents the film from sliding

heating mode can be selected from hot oven or heat plate.

the press roller adopts pneumatic method, which is convenient and labor-savin.

equipped with a yarn collecting box, waste yarn can be classified and collected.

a variety of yarn winder forms can be selected.

The cylindrical winder is larger and can reach the winding capacity of 30kg

4 inches, 10 inches winder: easy to assemble and unload, beautiful appearance

Recyclable materials and new materials.

High output, good performance, low cost, easy to operate, stable operation, low noise, automatic temperature control.

Strong technical team and rich experience, according to the customer's production needs to design the machine.

Professional pre-sale services to help you get accurate machines for your products.

Easy to control and adjust the system, making your production easier and faster.

Responsible for after-sales service, help you to install the machine, and gradually train you to use the machine

Company Strength

Hot Searches