NaN / 0

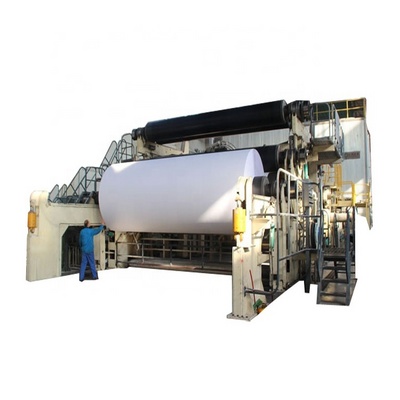

Factory Wooden/Bagasse/Rice straw/ Waste Paper Recycling Machine Tissue Paper Jumbo Rolls Making Machine For Toilet Paper Roll

Get Latest Price

US$ 65000

≥1 Sets

US$ 50000

≥2 Sets

Quick Details

Type:

Paper Cutting Machine

Production Capacity:

98%

Max. workable width:

1600mm

Place of Origin:

Shandong, China

Product Details

PRODUCRT SPECIFICATION

|

Used Toilet Paper Machine For Sale,Shandong Toilet Paper Machine Prices,Full Automatic Toilet Paper Machine Factory | |

| Paper Grams |

|

|

|

0.7-1T/D | |

|

30-50m/min | |

|

Ø1250mm | |

|

Ø700mm |

PRODUCRT SHOW

↑↑↑Click the process to watch the video↑↑↑

PRODUCT FEATURE

1) Reliable quality, stable performance, convenient operation, energy conservation, environmental protection

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) It is made up of molding, drying, transmission, pressing, walking platform and reeling parts.

4) Running in a high automatization and intellectualization.

5) Computer PLC control system with easy operation

1.Boiler type:steam boiler

2.Working medium:coal-fired

3.Rated pressure:1.0Mpa

1.Boiler type:steam boiler

2.working medium:diesel or natural gas fired

1.boiler type:steam boiler

2.working medium:electricity

3.Rated pressure:1.0Mpa

Main product parts:

Electrical control system:

·Our machine adopt PLC frequency conversion touch screen control system

·Easy operation,stable performance

Raw materials for paper pulps as following

WARM TIPS

·1.Before installation, you should check that equipment’s model and dimension are all right with the parts completed and level remaining.

·2.Before the debugging of installation,Checking each part is correct, lubrication supply normal. water, electricity values reaching the standard.

·3.During Operation, you should pay attention to keep daily inspection, cleaning and oiling, and then examine and repair regularly.

PAPER CONVERTING PRODUCTION LINE

1. Toilet roll paper machine

·Put the jumbo roll paper produced from paper machine to convey into toilet paper rewinding machine

·Then to process into band-saw cutting machine to produce small toilet roll

·Finally put the small toilet roll into plastic bag and sealed by sealing machine

2. Toilet paper converting machine

·Put the jumbo roll paper produced from paper machine to convey into toilet paper rewinding machine

·Then to process into automatic log cutting machine to produce small toilet roll

·Then put the small toilet roll into plastic bag for one roll packing

·Finally put packed paper roll into big plastic bag and sealed by sealing machine

3. Napkin paper making machine

·Put the jumbo roll paper produced from paper machine convey into slitting and rewinding machine to cut well rolled paper

·Then to print,emboss and automatically fold the rolled paper which is cut well into square or rectangular napkin paper

·Finally put napkin paper into napkin paper packing machine to pack into soft packed drawing napkin paper

4. Facial tissue paper machine

·Put the jumbo roll paper produced from paper machine convey into tissue paper machine to produce

·Then cut well into square or rectangular napkin paper through tissue cutting machine

·Finally put tissue paper into tissue paper packing machine to pack into soft packed drawing tissue paper

5. Full automatic facial tissue paper machine line

·This is a complete facial tissue paper production assembly line,which concentrate in facial tissue paper making machine,facial tissue slitting machine,full automatic facial tissue paper packing machine to produce soft packed facial tissue paper

MAIN PRODUCT

PRODUCTION CAPACITY Click here to learn more

OUR PACKING AND TRANSPORTATION Click here to learn more

FAQ

1.How to install and maintain the machine?

Firstly, we will provide the installation guild with the machine for your reference.

Secondly, our company is responsible for training production workers for you, ensuring that the workers will be independent operation.

2.How can we get the matching accessories or wearing parts conveniently?

During the warranty, Our company can replace the accessories for free .Out of warranty,we can provide them at the preferable price. In fact, the wearing parts are standard parts that you could get it in your country at your convenience.

Hot Searches