NaN / 0

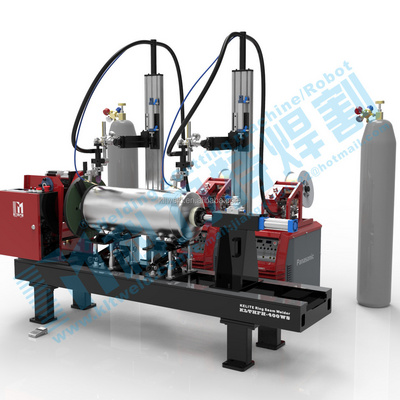

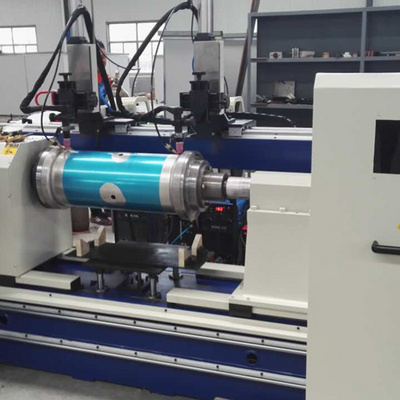

Solar Water Heater Tank Twin Head Circular Welding Machine for Side Cover

Get Latest Price

US$ 14000

≥1 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

HAOYU

Weight (KG):

2000

Voltage:

380V

Product Details

Automatic Water Tank Circumferential Air Compressor Gas Cylinder Girth Weld Circular Seam Welding Machine

NZC-HF

Automatic Water Tank Circumferential Air Compressor Gas Cylinder Girth Weld Circular Seam Welding Machine

Product Description automatic circular seam welder circumferentienal welding machine

1.Welding torch is fixed while work piece rotating, welding position is horizontal. One end of work piece is jigged by power head and rotates automatic circular seam welder circumferentienal welding machine

2.Two welding torches and two power sources work simultaneously to improve work efficiency.

3.Torch, spindle box and tailstock can be adjusted longitudinally to fit various kinds of welding.

4.Japan Omron PLC is adopted to control the machine to run and speed is adjusted by AC servo, which can improve the reliability of the equipment. automatic circular seam welder circumferentienal welding machine

5.Adopts end face positioning and pneumatically clamping mode.

6.Adopts human-machine interface to alter the parameters. The welding time and weld length can be set via this interface. The alteration of the parameters can be input through the touch button conveniently and timely. Parameters can be stored and called. a utomatic circular seam welder circumferentienal welding machine

Details Images automatic circular seam welder circumferentienal welding machine

Product Parameters

|

Applicable diameter |

200mm-800mm |

|

Applicable length |

max 2000mm |

|

Material |

carbon steel, stainless steel, aluminum |

|

Thickness |

1mm-3mm, 2-6mm |

|

Rotation speed |

0.2-2rpm |

|

Motor power |

0.55KW |

|

Welding torch moving range in left-right direction |

100mm |

|

Welding torch lifting range |

100mm |

|

welding torch moving range in front-rear direction |

50mm |

| welding moce | TIG,MIG,MAG,SAW |

Packaging & Shipping

⇒Normally we will use plywood case for packaging; for some big machine, we can use steel pallet and plastic filme cover.

⇒All machines are paint with anti rust paint or oil before leaving factory.

Hot Searches