NaN / 0

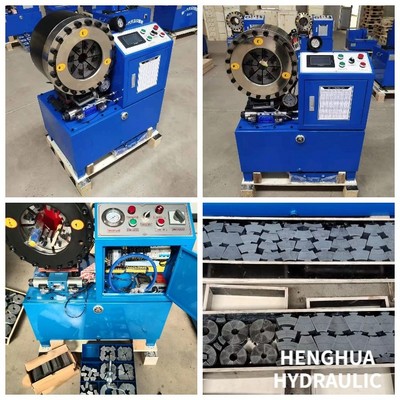

Factory Direct Sales DX76 Pipe Crimping Machine Industrial Hose Crimping Machine Hydraulic Hose Crimping Tool Harbor Freight

Get Latest Price

US$ 2780

≥1 Sets

US$ 2680

≥5 Sets

US$ 2388

≥10 Sets

Quick Details

Place of Origin:

Tianjin, China

Brand Name:

HENGHUA

Voltage:

220V/380V

Dimension(L*W*H):

820*570*1090mm

Product Details

Why Choose Us

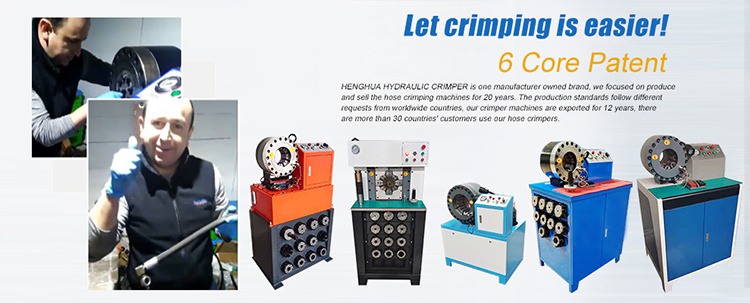

1. We are the only " Verified Supplier " among the Top 10 supplier of rubber product making machinery, and factory certified by Alibaba authorized

2. We are eligible to participate in the " Million Dollar Club ", have passed the audit, and are eligible to provide services to gold lbuyers who are expected to purchase more than one million U.S. dollars each year.

3. We are super strength factory , You will see the video of our factory on Alibaba's exclusive page.

4. We have 6 patented core technologies .

5. Our products are most popular in India, and sell well in more than 20 countries .

6. Similar products are cost-effective on quality and performance.

| Product Parameter | ||||

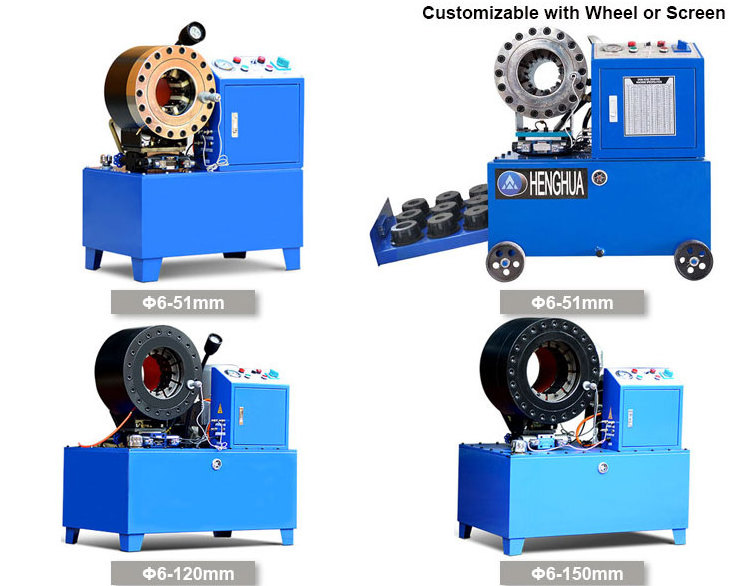

| Model | DX68 | DX76 | DX102 | DX150 |

| Crimping range |

6 ~ 51mm (1/4" ~2") |

6~76mm ( 1/4~3" ) |

6~102m ( 1/4~4" ) |

6-150mm (1/4~6") |

| Max crimping Force | 449T | 1000T | 1400T | 2100T |

| Rated Pressure | 31.5MPa | 31.5Mpa | 31.5Mpa | 31.5Mpa |

| Weight | 250kg | 360kg | 520kg | 800kg |

| Mold Quantity | 10 sets | 13Sets | 16Sets | 18Sets |

| Power | 3KW/4KW | 3/4/5.5KW | 4KW/5.5KW/7.5KW | 4KW/5.5KW/7.5KW |

| Voltage | 220V/380V | 110V-450V | 380V or customized | 380V or customized |

| Scale accuracy | 0.01mm | 0.01mm | 0.01mm | 0.01mm |

| Overall dimensions | 670*490*780mm | 820*570*1090mm | 900*790*1070mm | 100*600* 1050mm |

Brief Introduction

Our 3-inch hydraulic hose crimping machine is an advanced solution designed to meet your crimping needs with unparalleled precision and efficiency. With the option for a customizable touch screen version, it brings convenience and enhanced control to your operations.

Main Technical Feature

1.High Precision:

Our machine is engineered to deliver precise and uniform crimps on 3-inch hydraulic hoses. It ensures leak-free connections, promoting the safety and reliability of your hydraulic systems.

2.Customizable Touch Screen: With the touch screen version, you have intuitive control at your fingertips. Easily set and adjust parameters, monitor crimping processes, and access helpful guides and tutorials. The touch screen interface enhances user experience and simplifies operation.

3.Rapid Operation:

Equipped with a powerful hydraulic system, our machine offers swift and efficient crimping. It reduces downtime and increases productivity, allowing for high-volume production without compromising quality.

4.Versatility: Our machine accommodates various types of hydraulic hoses, providing flexibility for different applications. It can handle a wide range of hose sizes, allowing you to tackle diverse projects with ease.

5.Robust Construction: Built with durability in mind, our hydraulic hose crimping machine ensures long-lasting performance. It is constructed with high-quality materials, capable of withstanding demanding industrial environments.

>>Any color can be customized.

>>Machine parts can specify the brand requiryed by customers, such as Famous brand motors. >>Can customize customer's own logo and machine OEM.

>>Molds can be customized in different models.

Promise

We will provide a guarantee to keep the machine in good repair within 12 months from the day when the machine is purchased. All fitting troubles will be free of charge repaired (or replaced if necessary) during the guarantee period. The damage resulted from improper use o accident damage does not belong to free of charge repair range.

With quick Dies Change Tool (optional)

Packaging & Delivery

Relatived Rubber Hose Making Machinery Products

1.Hose Cutting Machine

2.Hose SKiving Machine

3.Rubber Hose,Hose assembly

4. Ferrule, Hose Fittings, Flange, Adapter,Clamp,etc

FAQ

1. What level of service do you provide ?

*Your inquiry will be replied in 24 hours.

*Eight continuous years as an Alibaba Gold supplier and more than 25 years industrial technology and manufacturing experience .

* We offer free spare parts and service within 14 month warranty period.

* Technology Support by providing operation training videos .

* Professional after-sales service team.

* Give reasonable offers with the best quality.

2. What is our advantages?

* Competitive price: We can meet your budget and best-selling business very well.

* OEM Accepted: We can produce customized design.

* Good Service: We treat clients as friends and provide problem solving anytime you need.

* Good Quality: We have strict quality control system. Good reputation in the market.

* Fast & Delivery: We have big discount from forwarder (Long-term Contract).

* Door To Door Service.

3. Can you customize the machine for the customer?

Yes. We can, we also provide OEM for customers; If you need customized services, please contact us

4. What is the MOQ?

We usually provide 1 set for customers to test.

Notices

1.When buckling, make the joint to locate the mould center as much as possible, the joint is not buckled on the hex nut.

2.Prevent tool and other foreign matter from entering the locking head.

3.After the work is finished for each time, the eight-block mould base must be made to extend to the greatest extent, this can make the spring to be at extension status. If not, the spring will be damage.

4.When working, the hand should not stretch into the locking head.

5.The power supply must be switched off when maintenance is done.

Maintenance and Care

The hydraulic oil in the oil tank should be frequently checked, if oil amount is found to be insuf- ficient, the oil shall be timely supplemented. If the oil liquid is polluted, it shall be filtered or replaced.

The locking head shall keep internal cleanliness. Avoid the foreign matters during processing to enter into the locking head oil cylinder via the mould to affect the normal use. Wipe out the foreign matters, which are brought by the mould body in time when buckling the joint.

Frequently fill suitable grease into the mould body for lubrication.

Hot Searches