NaN / 0

Factory Price Continuous Type Smokeless Rotary Carbonization Furnace / Coconut Shell Biochar Charcoal Making Machine

Get Latest Price

US$ 32500

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

TZ

Dimension(L*W*H):

9*2.6*2.9m

Voltage:

380V,50HZ, 3phase

Product Details

Product Description

Continuous carbonization furnace is mainly used for carbonization of biomass materials. Carbonized wood materials (less than 10 cm in volume) such as wood chips, rice husks, peanut husks, plant straws, bamboo chips, coconut husks, palm husks, bark, etc. are subjected to dry distillation. Ideal equipment for oxidation and high carbonization rate under high temperature conditions in the furnace .

Materials:

The materials of diameter is below 10cm,such as rice husks,sawdust,coffee grounds,coconut shells,etc. And the moisture is below 20%.

Spare part:

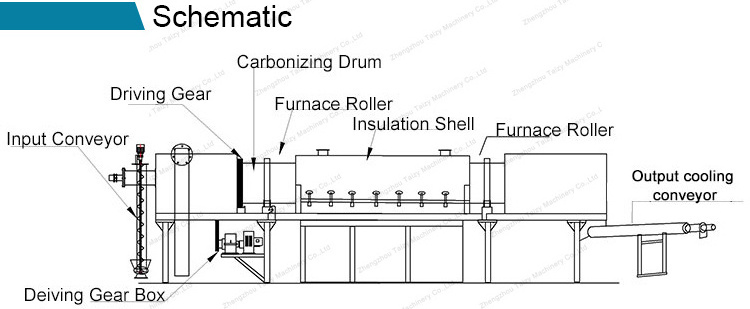

It is composed of the feeder,host,discharger,smoke cleaning equipment,bearing pool,ignition port and control cabinet. And there are five motors in total,which are respectively on the feeder,flat feeder,host,fan and discharger. And the smoke cleaning equipment has three cylinders,one is filled with corn cobs and shavings,and the other two are water,mainly for purification,need to be replaced every 3-6 months.

Product parameter:

|

Model |

Power |

Capacity |

Weight |

Size |

|

800 |

22kw |

300-500kg/h |

8t |

9*2.6*2.9m |

|

1000 |

25kw |

600-800kg/h |

10t |

10*1.6*3.5m |

|

1200 |

25kw |

800-1000kg/h |

13t |

11.2*1.65*1.5m |

Advantages:

Different from the energy-saving and environmentally-friendly continuous carbonization machine, it has two significant advantages: First, the main body is large, the carbonization rate is high, and the production capacity is strong. It can produce 0.3-0.8 tons of carbonized products per hour;

The second is low cost and strong practicability, which meets the objective requirements of small entrepreneurs with low initial investment and low income.

Factory

Packaging & Shipping

We can deliver the goods to you by sea, by air, by express or by land transportation. We will try my best to make you get the goods faster and safe.

Hot Searches