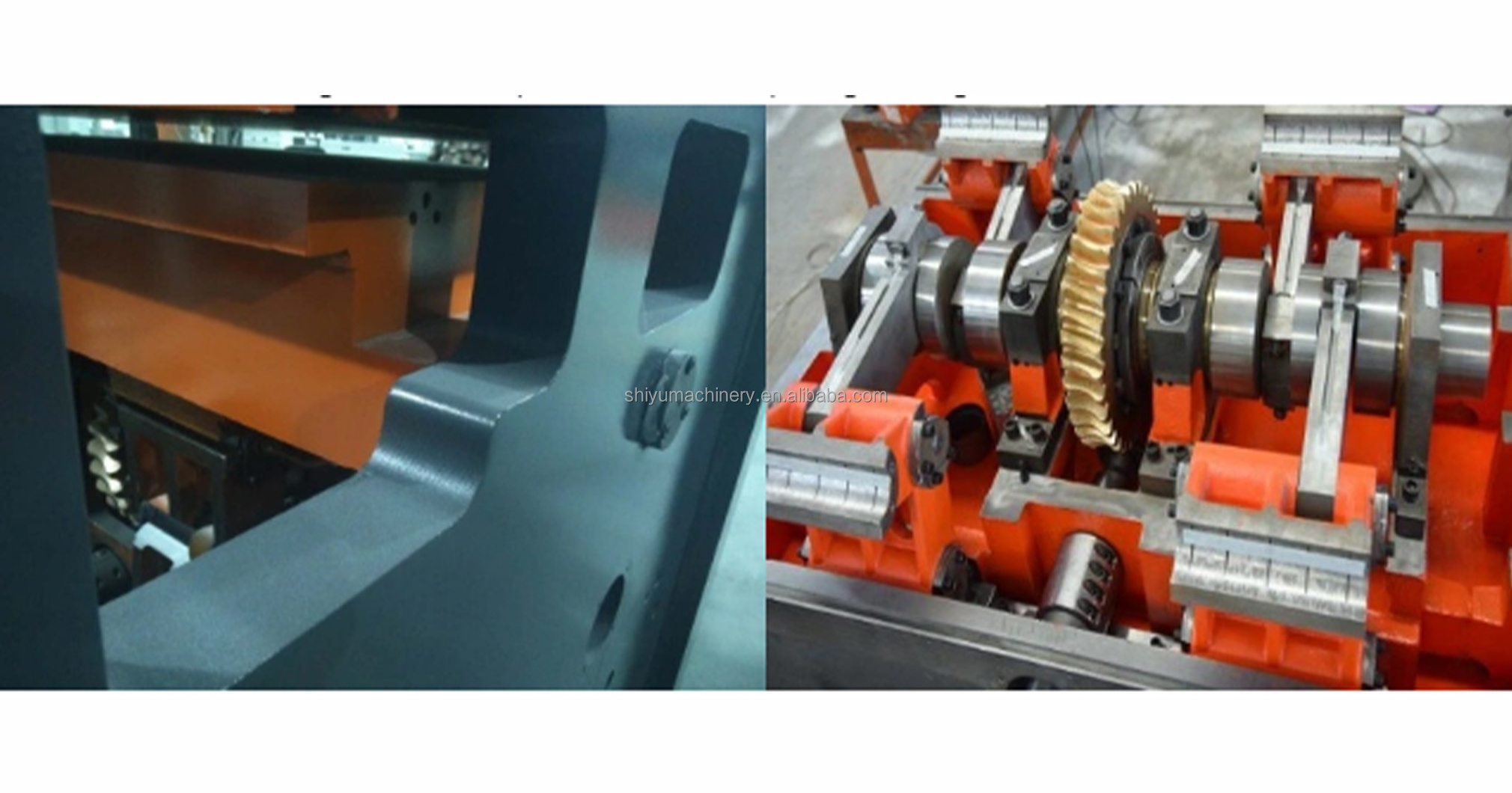

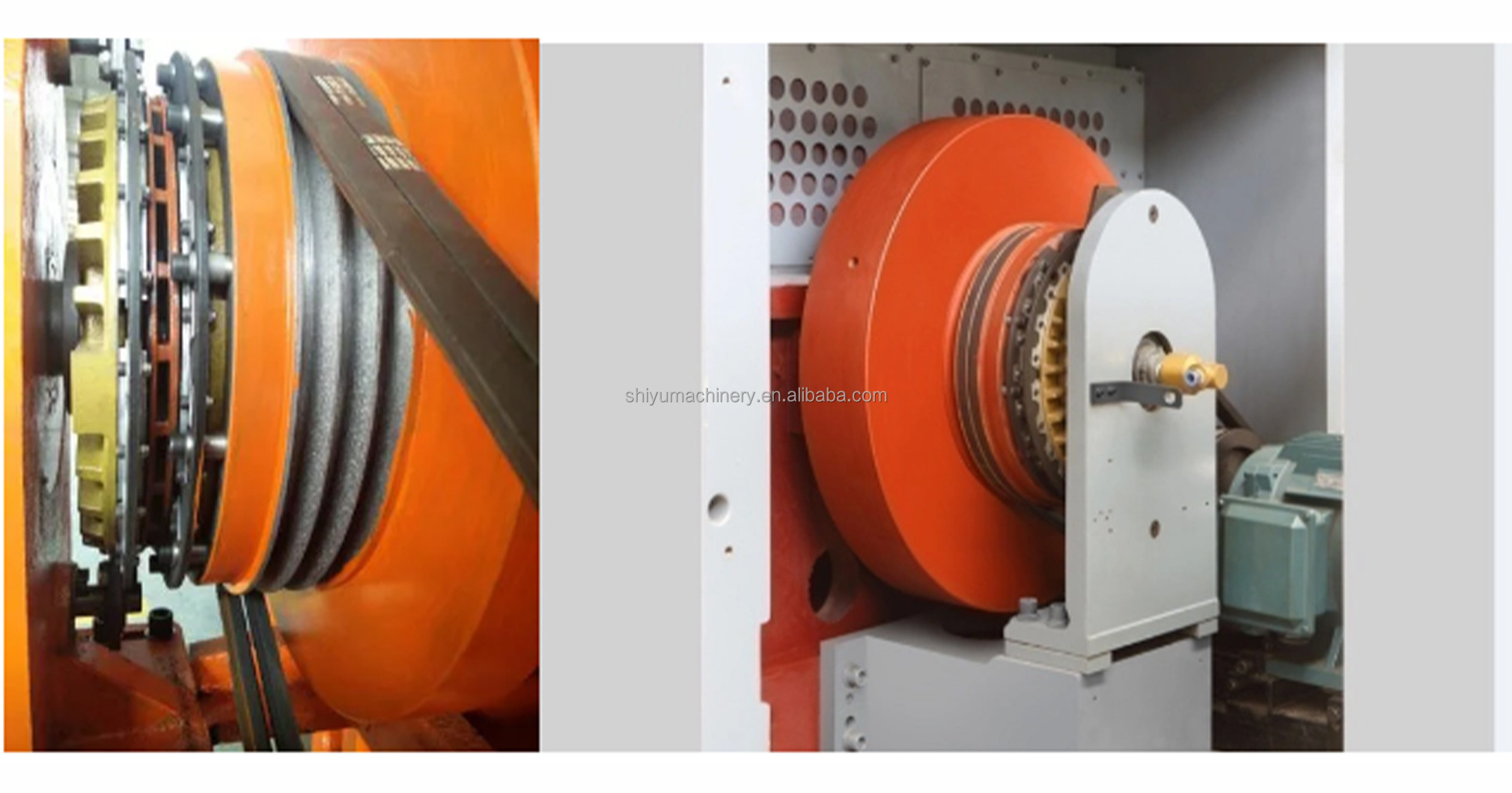

Perfect worm wheel and worm transmission system ensures the powerful and steady pressure and makes the

cutting accurately while the machine runs with high speed, has features of low noise, smooth running and high cutting pressure. Main base frame, moving frame and top frame are all adopts high strength Ductile Cast Iron , which has features of high tensile strength, anti-deformation and anti-fatigable.