NaN / 0

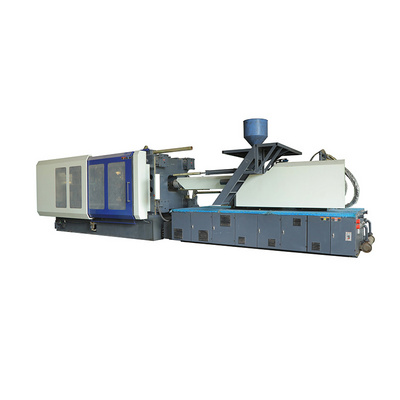

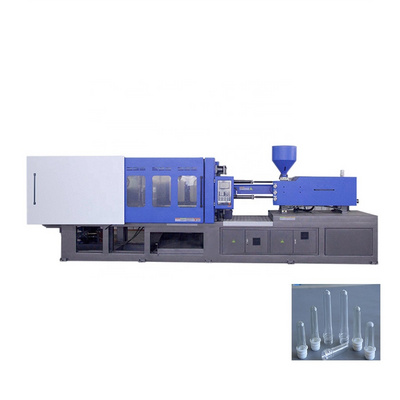

650 Ton Moulding Injection Molding Product Plastic Manufacturing Machine for Toys 915x915 Mm Distance Between Tie Bars

Get Latest Price

US$ 118857

≥1 Sets

US$ 73000

≥10 Sets

Quick Details

Distance between Tie Bars(Width)(mm):

915mm

Distance between Tie Bars(Height)(mm):

915mm

Mold Height(mm):

320 - 900 mm

Ejector Number:

16+1

Product Details

Products Description

|

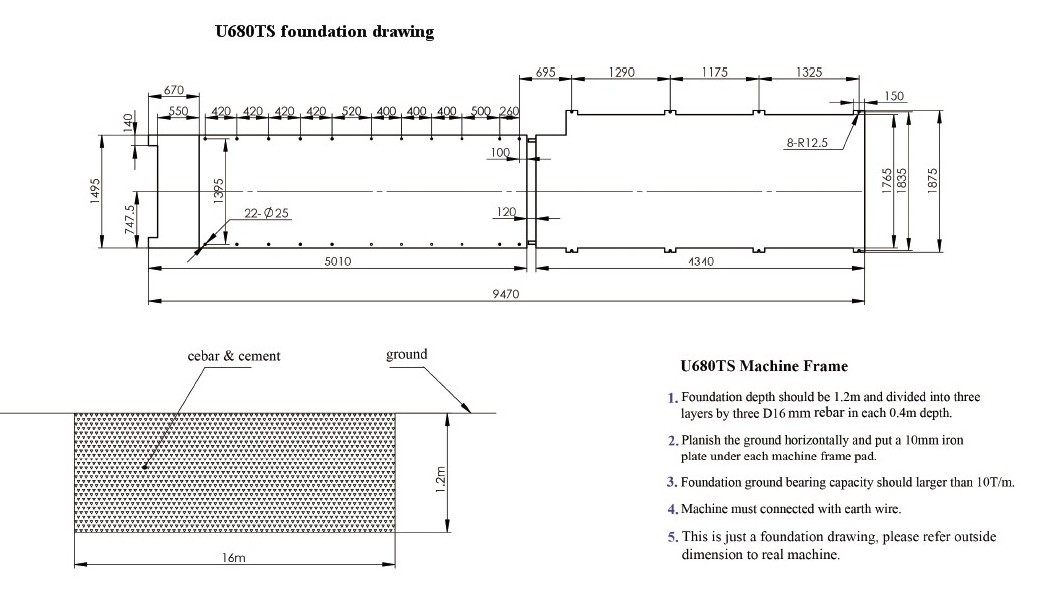

U680TS

|

Unit

|

A

|

B

|

C

|

D

|

|||||

|

INJECTION UNIT

|

|

|

|

|

|

|||||

|

SCREW DIAMETER

|

mm

|

90

|

95

|

100

|

110

|

|||||

|

SCREW L/D RATIO

|

L/D

|

23.2

|

22

|

20.9

|

19

|

|||||

|

SHOT VOLUME(THEORETICAL)

|

cm3

|

2816

|

3138

|

3477

|

4207

|

|||||

|

INJECTION PRESSURE

|

Mpa

|

176

|

158

|

142.6

|

117.8

|

|||||

|

SCREW SPEED

|

rpm

|

105

|

|

|

|

|||||

|

SHOT WEIGHT(THEORETICAL)(PS)

|

g

|

2562

|

2855

|

3164

|

3828

|

|||||

|

SHOT WEIGHT(THEORETICAL)(PS)

|

oz

|

90.407

|

100.734

|

111.607

|

135.064

|

|||||

|

CLAMPING UNIT

|

|

|

|

|

|

|||||

|

CLAMPING FORCE

|

Kn

|

6800

|

|

|

|

|||||

|

OPEN STROKE

|

mm

|

930

|

|

|

|

|||||

|

SPACE BETWEEN TIE BARS(W*H)

|

mm

|

915*915

|

|

|

|

|||||

|

MAX.MOULD HEIGHT

|

mm

|

900

|

|

|

|

|||||

|

MIN.MOULD HEIGHT

|

mm

|

320

|

|

|

|

|||||

|

EJECTOR STROKE

|

mm

|

265

|

|

|

|

|||||

|

EJECTOR FORCE

|

Kn

|

212

|

|

|

|

|||||

|

EJECTOR NUMBER

|

|

16+1

|

|

|

|

|||||

|

DIE HOLE DIAMETER

|

mm

|

200

|

|

|

|

|||||

|

OTHERS

|

|

|

|

|

|

|||||

|

SYSTERM PRESSURE

|

Mpa

|

16

|

|

|

|

|||||

|

MOTOR POWER

|

Kw

|

30+37

|

|

|

|

|||||

|

HEATING POWER

|

Kw

|

60

|

|

|

|

|||||

|

OIL TANK CUBAGE

|

L

|

1200

|

|

|

|

|||||

|

MACHINE WEIGHT

|

Ton

|

8+25

|

|

|

|

|||||

|

BOUNDARY DIMENSION(L*W*H)

|

m

|

5*2.1*3.1 6*2.5*2.5

|

|

|

|

|||||

|

SERVO DRIVER CAPACITY

|

Kw

|

37+45

|

|

|

|

|||||

Details Images

Product Advantages

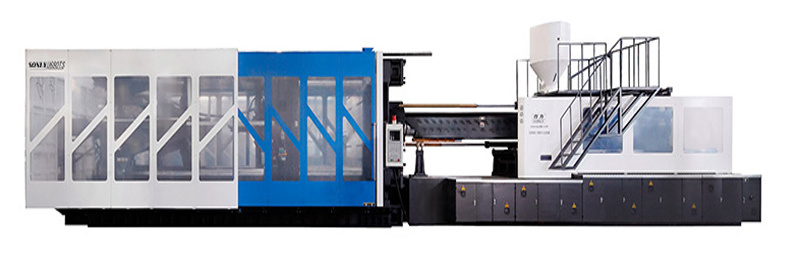

Sonly injection molding machine

has a large diameter ratio, faster plasticization speed, short drying cycle, and ultra-high plasticizer capacity provide guarantee for the high efficiency of the whole machine.

1. New conjoined hyperbolic elboe five fulcrum clamping mechanism, after a detailed calculation, manual and software running curve is more stable, smooth process is faster, and longer service life

2. New conjoined template through finite element analysis software, reasonable structure, convenient maintenance, good rigidity, high strength, small deformation

3. Electronic scale attached to cross, speed control is more agile, is conducive to protect the mould

4. Lubrication automatic detection alarm function, can effectively guarantee the lubrication of all nodes in place

5. Compared with the same, we have a bigger bar spacing, molar volume and open mold, processing more plastic products, the high cost performance of the machine

Recommend Products

Applications

Why Choose Us

FAQ

Hot Searches