NaN / 0

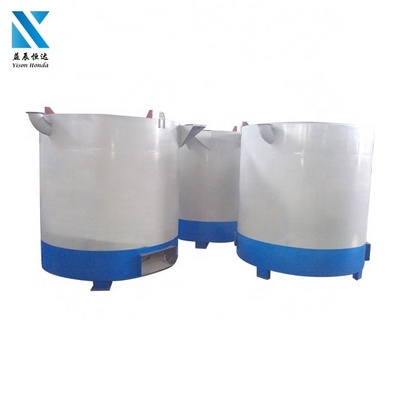

biochar kiln/sawdust charcoal carbonization stove/charcoal making stove

Get Latest Price

US$ 2200

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Name:

biochar kiln/sawdust charcoal carbonization stove/charcoal making stov

Height:

1500 mm

Thickness:

10 mm

Product Details

biochar kiln/sawdust charcoal carbonization stove/charcoal making stove

Product Description

Carbonization furnace for wood is also combined type. This kind of carbonization stove are included three inner stove, when one inner stove are finished, it can be hoisted outside. And when the first inner stove are cooling , the other inner stove can be carbonized at the same time, in this way the cooling time can be reduced much, thus, the productive efficiency increase a lot .This type of stove adopts the structure of unique air storage chamber, to fully reuse the smoke produced during the process of carbonization. And the redundant smoke can be used in drying and carbonizing, saving much fuel during the whole process, and increasing the enterprise revenue.

1. Heat

After sealing work, use wooden wastes or gas to heat furnace. Primarily, 10 minutes big fire to burn, when the temperature reaches 90 degrees centigrade, turn to use slow fire to heat. It takes 80-120minutes for this process to reduce water vapor from your materials.

2. Pyrolyse

Keep heating, when the temperature reaches 180-235 degrees centigrade for 3-5hours, it will produce gas from this process. Reuse this gas as fuel to heat. The whole process is about 8hours. When the temperature reach highest and it reduces, the dry distillation process will finished.

3. Cooling

Hang the Inner pot outside, and seal the pipes of cover. Let it cool naturally. Cooling time is longer, the quality of charcoal is good. When the temperature lowers than 50 degree, you can take charcoal out. Otherwise, the charcoal will burn again when met oxygen of air.

| Property | Units | Value |

| Type | YHDZ-150 | |

| Height | mm | 1500 |

| Thickness | mm | 10 |

| Diameter | mm | 1500 |

| Weight | ton | 5 |

| Labor Need | 2-3 | |

| Applicable Materials | Sawdust ,rice husk,wood chips,bamboo,coconut shell,palm shell,brances, | |

| Processing Temperature | ℃ | 400-500 |

| Production | KG/SHIFT | 600 |

| Shift Time | H | 4-8 |

| Charcoal Machine Parts | 3 outer stove 9 inner stoves with 9caps,one 5- ton hoisting equipment with e-motor ,smoking pipe |

Packaging & Shipping

Hot Searches